Product Details

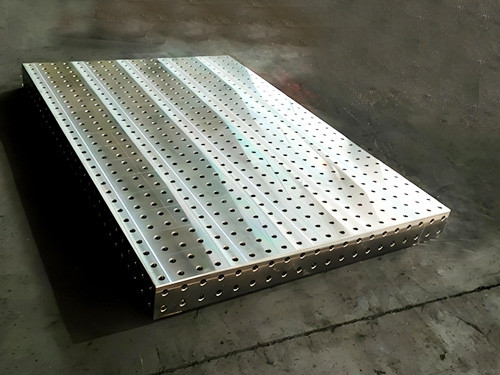

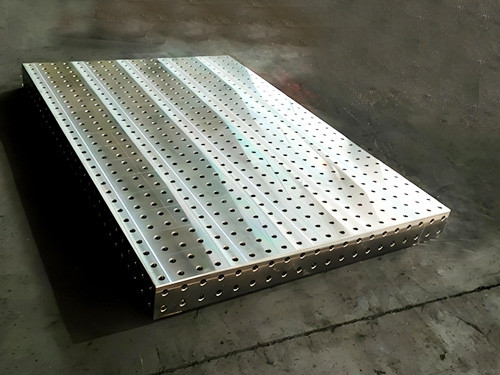

Custom Size 3D Welding Table

A custom-size 3D welding table is a specialized worktable designed for welding operations,featuring flexibility,high precision,and customizability.Here is a detailed introduction:

Characteristics

Customizable Dimensions:The most prominent feature of this kind of welding table is that it can be customized according to user requirements.Whether it is a small-size table for small-batch production or a large-scale one for large-scale industrial manufacturing,the size can be adjusted to meet different workspace and production needs.

Three-Dimensional Work Surface:Unlike traditional welding tables with only one working surface,a 3D welding table usually has five surfaces,including the top and four sides.This design allows for more flexible workpiece clamping and positioning,enabling welding operations from multiple angles and directions.The four side surfaces can be spliced arbitrarily through fixtures,similar to building blocks,which is convenient for use.

Grid-Hole Design:The work surface of the table is evenly distributed with circular holes of a certain diameter,usually 16mm or 28mm,which are arranged in an array with a certain pitch.The D16 series has a hole pitch of 50mm±0.05,and the D28 series has a hole pitch of 100mm±0.05.These grid-holes are used in combination with flexible welding fixture clamps to accurately position and fix workpieces,improving the accuracy and repeatability of welding.

Structural Components

Work Surface:Usually made of high-quality steel or cast iron materials.Steel-made work surfaces(such as Q355 steel)have high strength and toughness,while cast-iron work surfaces(such as HT250 or HT300 cast iron)have good wear-resistance,heat-resistance,and shock-absorption properties.The work surface undergoes precision machining to ensure flatness and perpendicularity,with a surface finish of 1.6μm.

Supporting Structure:The supporting structure of the welding table is usually made of steel profiles and is designed with reinforcing ribs on the underside to enhance the stability and load-bearing capacity of the table.It can be equipped with legs or a steel frame for support,and the feet can be customized with options such as adjustable leveling feet or casters for easy movement and leveling.

Fixture Accessories:Including positioning angle rulers,positioning flat rulers,U-shaped and L-shaped square boxes,support angle irons,fixed-type and telescopic-type pressure-tighteners,spiral pressure-tighteners,quick-locking pins,etc.These fixture accessories are made of high-quality steel materials and undergo heat treatment and surface treatment to ensure their strength,accuracy,and durability.

Applications

Automobile Manufacturing:In the production of automobile bodies,the custom-size 3D welding table can be used to clamp and position various components such as car doors,hoods,and chassis,ensuring the accuracy and quality of welding and improving production efficiency.

Mechanical Equipment Manufacturing:For the manufacturing of mechanical equipment,such as the welding of machine tool frames,equipment casings,and transmission components,the 3D welding table can provide a stable working platform and precise positioning,which is beneficial for ensuring the dimensional accuracy and assembly quality of products.

Metal Structure Processing:In the processing of metal structures such as steel bridges,building steel structures,and industrial pipelines,the custom-size 3D welding table can meet the welding needs of different-sized workpieces,facilitating the assembly and welding of components and improving the overall quality of the structure.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province