Product Details

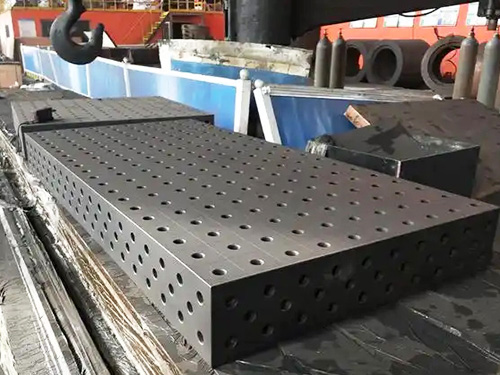

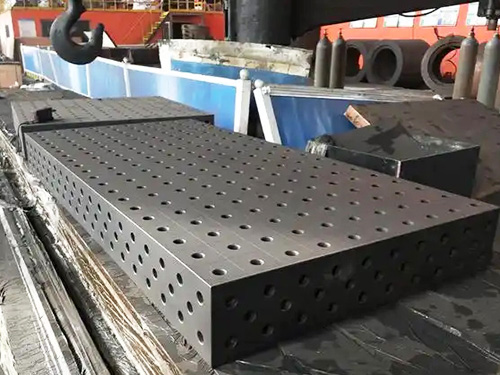

Heat Resistant Welding Platform

A Heat Resistant Welding Platform is a specialized work surface designed to withstand the high temperatures generated during welding operations.Here is a detailed introduction:

1.Key Features

High Temperature Resistance:As the name suggests,the most prominent feature of this platform is its ability to resist high temperatures.It is typically made from materials such as refractory ceramics,high-temperature resistant alloys(e.g.,Inconel),or heat-treated steels.These materials can endure the intense heat from welding arcs,flames,or molten metal without deforming,melting,or losing their structural integrity.For example,refractory ceramics can withstand temperatures well above 1000°C,making them ideal for high-intensity welding processes.

Thermal Stability:In addition to high temperature resistance,a good heat resistant welding platform also exhibits excellent thermal stability.This means that it can maintain its mechanical and physical properties even after repeated cycles of heating and cooling.This property is crucial to ensure consistent performance during welding operations,as it prevents issues such as cracking or warping that could affect the quality of the welds.

Abrasion and Corrosion Resistance:Welding often involves the use of various tools and the presence of sparks,slag,and corrosive substances.A heat resistant welding platform is designed to be resistant to abrasion caused by these factors.It also has a certain level of corrosion resistance to protect against the effects of welding fluxes and other chemicals used in the process.

Flat and Stable Surface:To ensure accurate welding,the platform has a flat and stable surface.This helps in proper alignment and positioning of the workpieces,reducing the chances of errors and ensuring the quality of the welds.The surface may be machined to a high degree of precision to meet the requirements of different welding applications.

2.Construction and Materials

Materials:

Refractory Ceramics:These are inorganic,non-metallic materials that can withstand extremely high temperatures.They are often used in applications where very high heat resistance is required,such as in the welding of high-melting-point metals.

High-Temperature Alloys:Alloys like Inconel,which is a nickel-chromium-based alloy,are known for their excellent heat resistance,strength,and corrosion resistance.They can be used to fabricate the structural components of the welding platform,providing both heat resistance and mechanical strength.

Heat-Treated Steels:Certain types of steels,such as tool steels,can be heat-treated to enhance their heat resistance and hardness.These steels are commonly used in the construction of the platform's frame or base,as they offer a good balance between cost and performance.

Construction:The platform usually consists of a top surface made of the heat resistant material,supported by a sturdy frame.The frame is often made of steel or other strong materials to provide stability and support.In some cases,insulation materials may be incorporated between the top surface and the frame to prevent heat transfer to the underlying structure.

3.Applications

Industrial Welding:In industrial settings such as manufacturing plants,shipyards,and construction sites,heat resistant welding platforms are essential for welding a wide range of materials,including metals like steel,aluminum,and copper.They are used in the production of large structures,machinery parts,and pipelines.

Aerospace and Defense:In the aerospace and defense industries,where high-quality and precision welding are critical,heat resistant welding platforms play a vital role.They are used for welding components of aircraft engines,missile parts,and other high-performance equipment that require the use of advanced welding techniques and materials.

Automotive Manufacturing:In the automotive industry,heat resistant welding platforms are used for welding engine components,exhaust systems,and other parts that are exposed to high temperatures during operation.They help ensure the durability and reliability of these components.

4.Maintenance and Care

Cleaning:Regular cleaning is necessary to remove slag,sparks,and other debris that accumulate on the surface during welding.This can be done using appropriate cleaning tools and solvents,taking care not to damage the heat resistant surface.

Inspection:Periodic inspection of the platform for any signs of damage,such as cracks,warping,or wear,is important.Early detection of such issues can prevent further damage and ensure the continued safe and effective operation of the platform.

Protection:When not in use,the platform can be covered to protect it from dust,moisture,and other contaminants.This helps to maintain its performance and extend its lifespan.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province