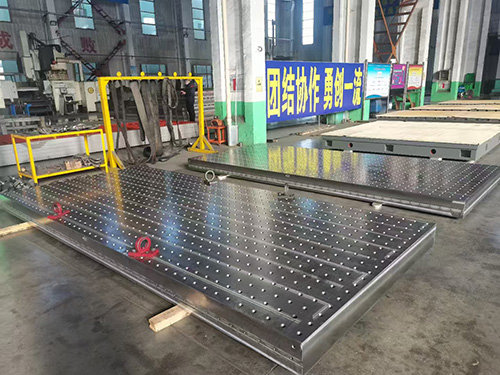

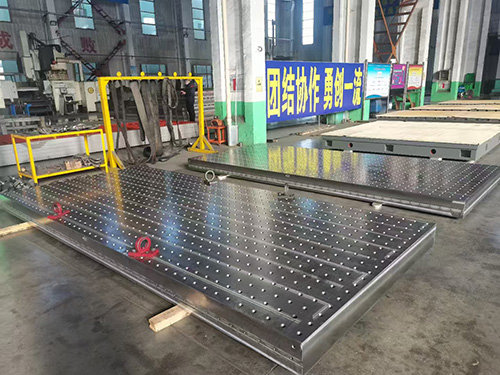

Product Details

Heat Resistant Welding Table

A heat-resistant welding table is an essential piece of equipment in welding workshops,designed to withstand the high temperatures generated during the welding process.Here is a detailed introduction:

Characteristics

High-Temperature Resistance Materials:The tabletop of a heat-resistant welding table is typically made of materials with excellent heat-resistant properties,such as refractory ceramics,high-chromium alloy steels,or graphite-based composites.These materials can endure temperatures ranging from 800°C to 1500°C,depending on the specific material and application.For example,some refractory ceramic-coated tabletops can withstand temperatures up to 1200°C,providing reliable heat resistance for various welding tasks.

Thermal Insulation Design:To prevent heat from transferring to the underlying structure and the surrounding environment,heat-resistant welding tables often incorporate thermal insulation layers.These layers are usually made of materials like ceramic fiber blankets or mineral wool,which have low thermal conductivity.The insulation layer can reduce heat loss by up to 50%-70%,helping to maintain the working temperature of the tabletop and protect the equipment and personnel around it.

Structural Stability:Despite the high-temperature environment,heat-resistant welding tables need to maintain excellent structural stability.The frame is usually constructed from high-strength steel or alloy materials that are resistant to thermal deformation.Additionally,the design of the table often includes reinforced supports and a rigid framework to ensure that the table can withstand the weight of the workpieces and the mechanical stress during welding,even at high temperatures.

Advantages

Extended Service Life:The use of heat-resistant materials and proper thermal insulation helps to prevent the tabletop from warping,cracking,or deforming due to heat.This significantly extends the service life of the welding table,reducing the frequency of replacements and maintenance,and ultimately saving costs for the workshop.A well-maintained heat-resistant welding table can last for 10-15 years,compared to 5-8 years for a regular welding table in high-temperature welding applications.

Improved Welding Quality:A stable and heat-resistant tabletop provides a consistent and reliable platform for welding.It helps to minimize thermal distortion of the workpieces,ensuring more accurate welds and better overall welding quality.The ability to maintain a relatively stable temperature on the tabletop also allows for better control of the welding process,as the heat-affected zone can be more precisely managed.

Enhanced Safety:By effectively resisting heat and reducing heat transfer,heat-resistant welding tables contribute to a safer working environment.They prevent accidental burns to operators and reduce the risk of fire or damage to nearby flammable materials.The stable structure of the table also ensures that it will not collapse or malfunction under high-temperature conditions,further enhancing the safety of the welding operation.

Applications

High-Temperature Welding Processes:Heat-resistant welding tables are widely used in various high-temperature welding processes,such as plasma arc welding,electron beam welding,and some types of oxy-fuel welding.In plasma arc welding,where the arc temperature can reach up to 20,000°C,the heat-resistant table provides a stable and reliable platform to support the workpiece and withstand the intense heat.

Metal Fabrication and Repair:In metal fabrication shops and repair facilities,heat-resistant welding tables are essential for working with high-temperature-resistant alloys and metals.When welding components made of stainless steel,nickel-based alloys,or titanium,which often require high-temperature welding techniques,the heat-resistant table ensures that the workpieces are properly supported and that the welding process is carried out smoothly.

Aerospace and Automotive Industries:These industries often deal with high-strength and heat-resistant materials in the manufacturing of aircraft components,engine parts,and automotive exhaust systems.Heat-resistant welding tables are used to ensure the quality and integrity of the welds in these critical applications.For example,in the aerospace industry,the welding of turbine blades made of superalloys requires a heat-resistant table to maintain the precise shape and dimensions of the blades during welding.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province