Product Details

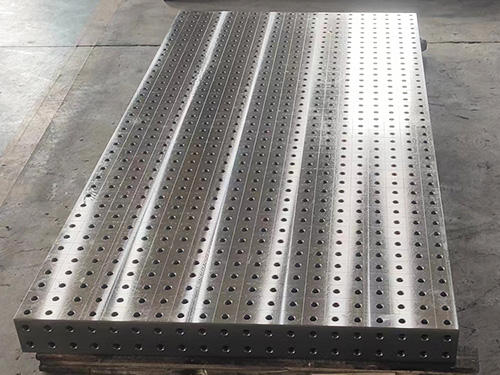

Heavy Duty Welding Table

The Heavy Duty Welding Table is a specialized equipment designed to handle heavy and high-strength welding tasks, playing an indispensable role in industrial production and other fields. The following is a detailed introduction to it:

Strong load-bearing capacity: The primary feature of heavy-duty welding workbenches is their exceptional load-bearing capacity. It usually uses high-strength materials such as thick steel plates, heavy-duty steel, or cast steel to construct frames and countertops, which can withstand weights of several tons or even tens of tons. For example, some heavy-duty welding workbenches used in large industries have a tabletop thickness of over 20mm. The frame structure has been carefully designed and reinforced to easily support large workpieces and heavy-duty welding equipment, meeting the needs of industries such as heavy machinery manufacturing and shipbuilding.

Durable and sturdy structure: In order to adapt to harsh welding working environments and high-strength usage requirements, the structural design of heavy-duty welding workbenches is very sturdy. The framework generally adopts a rigid welded structure, and each connecting part is finely processed and high-strength welded to ensure the stability and rigidity of the overall structure. At the same time, the worktable undergoes special treatments such as surface quenching and wear-resistant coatings to enhance its wear resistance and impact resistance. It can withstand high temperatures, sparks, and mechanical collisions generated during the welding process, extending the service life of the worktable.

Large workspace: Heavy duty welding workbenches typically have a large working area to meet the welding needs of large workpieces. The length, width, and height of the workbench have been optimized to provide spacious operating space, making it easy for operators to perform all-round welding operations. Some large heavy-duty welding workbenches can reach lengths of several meters and widths of over one meter, providing ample platforms for welding large structural components.

Multi functional design: In addition to the basic welding support function, the heavy-duty welding workbench also has multiple practical functions. There are usually standard T-slots, bolt holes, or fixture mounting holes on the countertop, which facilitate the installation of various types of fixtures and positioning devices to fix the workpiece and ensure the accuracy of the welding position. In addition, some heavy-duty welding workbenches are equipped with power sockets, gas interface and other facilities, which facilitate the connection of welding equipment and auxiliary tools and improve work efficiency.

Stability and seismic resistance: During heavy-duty welding processes, significant vibrations and impact forces are generated, so heavy-duty welding workbenches need to have good stability and seismic resistance. Its bottom is usually equipped with heavy-duty casters or anchor bolts, which can facilitate the movement of the workbench, while the anchor bolts can firmly fix the workbench on the ground, ensuring that the workbench will not shake or shift during the welding process. At the same time, the structural design of the workbench also considers seismic factors, which can effectively absorb and disperse the vibration generated during the welding process, ensuring the welding quality.

Application areas: Heavy welding workbenches are widely used in industries such as heavy machinery manufacturing, shipbuilding, bridge construction, and mining equipment maintenance. In these industries, welding processing is required for large metal structural components, and heavy-duty welding workbenches have become indispensable equipment due to their strong load-bearing capacity, sturdy structure, and multifunctionality.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province