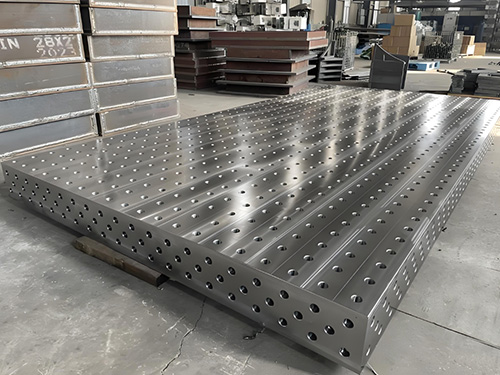

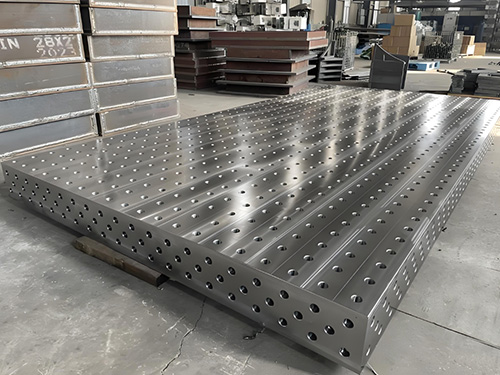

Product Details

Magnetic Welding Fixtures

Magnetic welding fixtures are tools used in welding processes to hold and position workpieces accurately with the help of magnetic force.Here is a detailed introduction:

Working Principle

Magnetic welding fixtures utilize the attractive force of magnets to secure workpieces.They usually consist of permanent magnets or electromagnets.Permanent magnets provide a constant magnetic force,while electromagnets allow for adjustable magnetic strength by controlling the electric current.When the workpieces are placed in the magnetic field,the magnetic force pulls them firmly against the fixture,holding them in the desired position for welding.

Types

Permanent Magnet Fixtures:These fixtures use permanent magnets to generate a fixed magnetic field.They are simple in structure,require no external power supply,and are suitable for applications where the magnetic force requirement is relatively stable.For example,in some small-scale welding workshops,permanent magnet fixtures are used to hold thin-walled metal sheets during spot welding.

Electromagnetic Fixtures:Electromagnetic fixtures use electromagnets,which offer the advantage of adjustable magnetic force.By varying the current passing through the coil of the electromagnet,the magnetic strength can be precisely controlled according to the specific needs of the welding process.This type of fixture is commonly used in industries such as automotive manufacturing and aerospace,where high-precision positioning and strong clamping forces are required for different types of workpieces.

Advantages

High-Precision Positioning:Magnetic welding fixtures can accurately position workpieces,ensuring high-quality welds.The magnetic force evenly distributes around the workpiece,holding it in a stable position without causing deformation.This is crucial for welding applications that require strict dimensional accuracy,such as in the production of electronic components or precision mechanical parts.

Quick Installation and Removal:Workpieces can be easily and quickly placed onto the magnetic fixtures and removed after welding.This significantly reduces the setup time for each welding operation,improving work efficiency.In mass-production welding lines,the rapid installation and removal of workpieces using magnetic fixtures can increase the production rate.

Versatility:Magnetic welding fixtures can be used with a variety of metal workpieces,including ferrous and non-ferrous metals.They can be designed in different shapes and sizes to accommodate different workpiece geometries and welding requirements.For example,some magnetic fixtures are designed with multiple magnetic poles to hold complex-shaped workpieces,while others can be adjusted to different angles for welding at various positions.

Disadvantages

Limited Magnetic Force:The magnetic force of fixtures has limitations.For very heavy or large workpieces,the magnetic force may not be sufficient to hold them firmly,especially in high-vibration welding environments.In such cases,additional mechanical clamping methods may be needed to supplement the magnetic force.

Sensitivity to Magnetic Fields:Magnetic welding fixtures are sensitive to external magnetic fields,which can affect their performance.In some industrial environments where there are strong electromagnetic fields,such as near large-scale motors or transformers,the magnetic fixtures may experience interference,leading to unstable clamping of workpieces.Special shielding measures may be required to ensure the normal operation of the fixtures.

Heat Generation:In the case of electromagnetic fixtures,continuous use may lead to heat generation in the electromagnet coils.This not only affects the magnetic force but also requires proper cooling measures to prevent damage to the fixture and ensure its long-term stable operation.Overheating of the coils can reduce the efficiency of the magnetic fixture and even cause it to fail.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province