Product Details

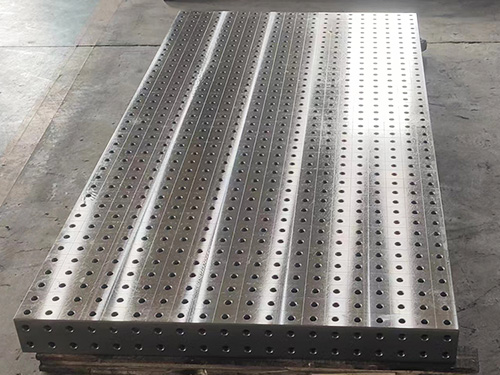

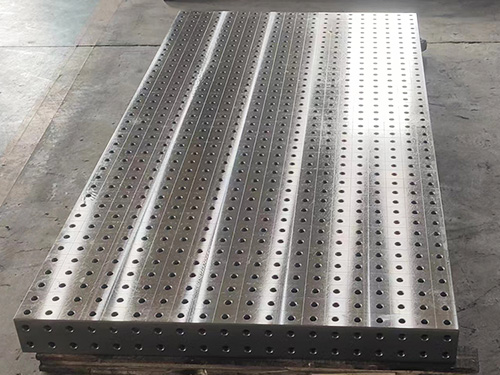

Modular Welding Table

Modular Welding Table is a professional welding operation platform with high flexibility and customization features.By freely combining modules with different functions,it meets diverse welding needs and has become an important tool in the modern welding field.

Modular design:The biggest feature of modular welding workbench is its unique design concept.It consists of multiple independent and standardized modules,such as workbench module,fixture module,shelf module,power integration module,etc.These modules can be quickly assembled,disassembled,and reassembled through precise interface design.For example,when welding large workpieces,an expansion table module can be added;When handling small precision components,install specialized positioning fixture modules to meet the complex and diverse welding task requirements.

Flexibility and adaptability:This workbench can flexibly adjust its structure and layout according to different welding projects,workpiece sizes,and operating procedures.Welding personnel can freely combine modules and build the most suitable work platform according to the actual work scenario.Whether it is automobile manufacturing,mechanical processing,steel structure construction,or daily maintenance welding,modular welding workbenches can be perfectly adapted to various working environments and process requirements through module adjustment.

Efficient and convenient:Standardized module design makes the welding workflow more efficient.When changing welding tasks,there is no need to rearrange the entire workbench,only replace or add corresponding modules,greatly saving preparation time.At the same time,the modular structure is convenient for handling and storage.When not in use,modules can be disassembled and stored to reduce space occupation,and can be quickly assembled and put into use when needed.

Quality and stability:Modular welding workbenches are usually made of high-strength steel,which has good load-bearing capacity and stability,and can withstand high temperatures,vibrations,and pressures generated during the welding process.The connection method between modules has been carefully designed to ensure a sturdy structure after splicing,providing a stable and reliable operating platform for welding operations and helping to improve welding quality and accuracy.

Function integration and expansion:In addition to basic welding operation functions,modular welding workbenches can also integrate various practical functions.For example,some modules come with built-in power sockets and cable management systems,making it convenient for welding equipment to use electricity and organize wiring;Some are equipped with smoke exhaust and dust removal modules to improve the working environment and ensure the health of operators;Some modules are designed with measurement scales and positioning benchmarks for precise operation.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province