Product Details

Modular Welding Table Extension Kits

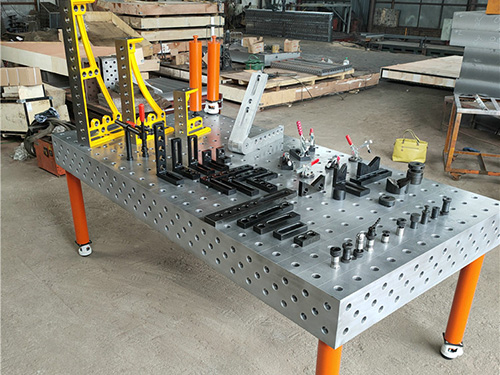

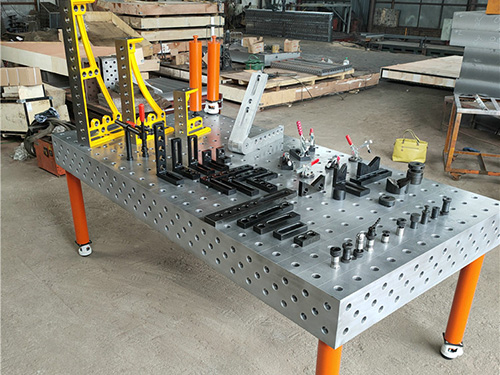

The modular Welding Table Extension Kit is an innovative solution that breaks through the functional boundaries of traditional welding stations. Through standardized and combinable component design, the welding station can achieve functional upgrades and size extensions, easily meeting diverse production needs and injecting new energy into cost reduction and efficiency improvement for enterprises!

1、 Free combination, customized exclusive workbench according to needs

The kit includes a variety of functional modules, such as extended workbenches, adjustable brackets, specialized fixture modules, and integrated tool racks. Through a unified quick connect interface, splicing can be completed within 15 minutes. Whether it is extending the length of the workbench, adding workstations, or stacking multiple layers of workspace, it can be freely combined to meet the welding needs of precision small parts to large structural parts. For example, adding a rotating workbench module can achieve 360 ° all-round welding; Assemble magnetic adsorption plates to easily fix thin sheet workpieces, greatly improving operational convenience.

2、 High strength material, capable of stably carrying complex working conditions

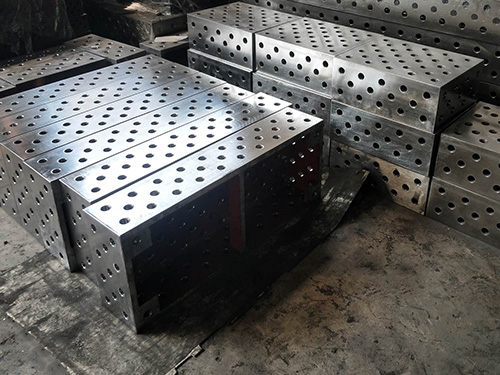

All modules are made of high-strength alloy steel, strengthened by heat treatment and precision machining. The single expansion table can bear up to 1 ton, and the support structure has passed fatigue testing to ensure stability in harsh environments such as heavy welding and high-frequency vibration. The special wear-resistant coating on the surface effectively resists welding slag splashing and high temperature erosion, extends the service life, and reduces maintenance costs.

3、 Compatible with mainstream devices and seamlessly integrated into existing production lines

Designed according to industry standards, the expansion kit is compatible with over 90% of welding station models on the market, and can quickly match T-slots, grid holes, and positioning pin interfaces. Without the need to replace existing equipment, functional expansion can be achieved by stacking modules, helping enterprises flexibly respond to order changes, reduce equipment upgrade costs, and improve production line flexibility.

4、 Multi scenario application, covering the needs of the entire industry

From assembly line welding in automobile manufacturing to large-scale component assembly in shipbuilding industry; From customized production of hardware processing to innovative testing in research laboratories, modular expansion kits can provide adaptation solutions. We have successfully assisted 3C electronics companies in expanding their small-sized precision welding stations, and helped mechanical processing enterprises complete multi station collaborative welding of large equipment components, becoming the "master key" to improve production efficiency.

Choosing a modular welding station expansion kit means choosing to achieve maximum capacity upgrade with minimal cost! With flexible and versatile combinations and rock solid quality assurance, let your welding station evolve into an intelligent workstation that meets all your needs!

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province