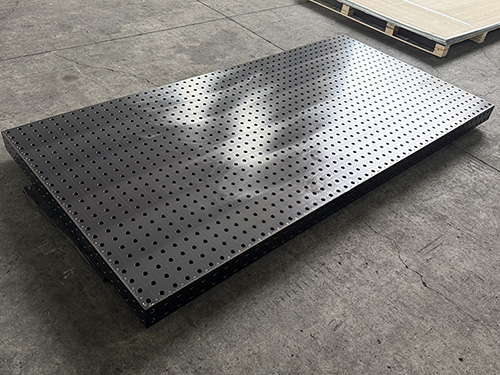

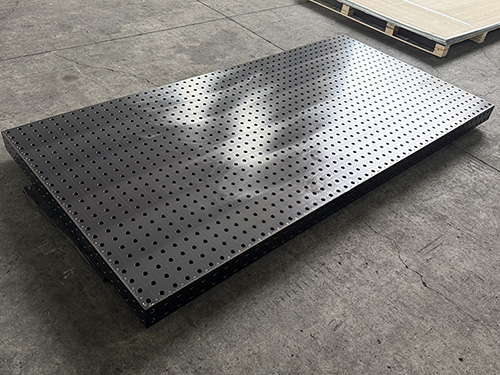

Product Details

modular welding table Wholesale distributor from China

We are a wholesale distributor of modular welding stations in China,and our advantages are:

1、Innovative modular design,flexible adaptation to diverse needs

Our modular welding station breaks through the limitations of traditional welding equipment and adopts a highly flexible modular design concept.Each component is a standardized module that can be freely combined,quickly disassembled,and reconfigured like building blocks according to different welding tasks,workpiece sizes,and shapes.Whether it's welding small precision electronic components or assembling large engineering machinery structural components;Whether it's assembly line operations in automobile manufacturing or high-precision component welding in the aerospace field,with simple operations,you can quickly adjust the layout and functions of the workbench,easily meet the diverse production needs,greatly reduce equipment idle rates,and make the most of every investment you make.

2、High precision positioning system ensures zero welding error

The workbench is equipped with a high-precision grid and T-groove system,with a positioning accuracy of±0.05mm,providing precise positioning benchmarks for workpieces.During the welding process,with the use of high-performance fixtures and positioning devices,the workpiece can be firmly fixed,effectively avoiding welding errors caused by displacement or shaking,ensuring that every weld seam is accurate and perfectly meets high quality requirements.For welding operations that require extremely high precision,such as automotive parts and aerospace structural components,our modular welding station can significantly reduce scrap rates,improve product qualification rates,and safeguard your brand's quality reputation.

3、High quality materials and exquisite craftsmanship create outstanding and durable quality

The main frame is made of high-strength alloy steel material and processed through special heat treatment technology,endowing it with excellent wear resistance,corrosion resistance,and compressive strength.It can easily withstand high temperature,high pressure,and heavy load welding environments.Even under long-term high-intensity use,it is not easily deformed or damaged,with a service life of over 10 years.At the same time,each welding station undergoes multiple strict quality inspection processes before leaving the factory,including material performance testing,structural strength testing,positioning accuracy calibration,etc.,to ensure stable and reliable product quality.It has passed ISO 9001 international quality management system certification and CE certification,meeting the strict standards of many countries and regions around the world,allowing you to purchase and use with peace of mind.

4、Significantly improve production efficiency and reduce overall costs

The rapid reassembly feature of modular welding stations can shorten equipment adjustment time from a few hours in traditional welding stations to less than 15 minutes,significantly reducing production preparation time and significantly improving equipment utilization and production efficiency.In addition,its high-precision positioning and stability performance can effectively reduce rework and repair costs during the welding process;The long-lasting and durable quality further reduces the cost of frequent equipment replacement and maintenance.In the long run,choosing our modular welding station means choosing a higher return on investment,saving the company a lot of manpower,material resources,and financial resources.

5、Widely used in multiple industries worldwide and receiving numerous praises

At present,our modular welding station has been successfully exported to more than 30 countries and regions in Europe,America,Asia,Australia,etc.It is widely used in various industries such as automobile manufacturing,aerospace,mechanical processing,electronic and electrical,and building decoration.Assist in achieving efficient and precise welding of body parts on German automotive production lines;Meeting the high-precision welding requirements of aircraft structural components in American aerospace companies;Provide reliable support for welding small electronic device casings in Japanese electronics manufacturing workshops.With excellent product performance and attentive service,we have gained high recognition and unanimous praise from customers worldwide.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province