Product Details

Precision Welding Table

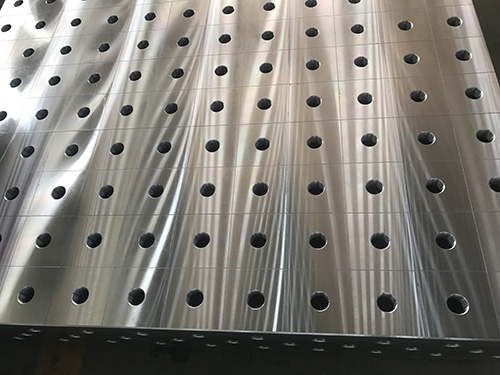

Precision Welding Table is a specialized equipment designed and manufactured specifically to meet high-precision welding requirements, playing a key role in many fields that require high welding quality and accuracy. Here is a detailed introduction for you:

High precision manufacturing: The precision welding workbench is extremely sophisticated in manufacturing technology, using high-precision machining techniques and high-quality materials. Workbenches are usually made of high-strength steel or cast iron that has undergone special treatment, with extremely high surface flatness and minimal flatness tolerance. For example, the flatness of some high-end precision welding workbenches can be controlled within ± 0.1mm to ensure the stability and levelness of the welded workpiece placement, providing a basic guarantee for high-precision welding.

Accurate positioning system: Equipped with advanced positioning system is an important feature of precision welding workbench. Common positioning methods include high-precision scale lines, positioning holes, T-shaped slots, and adjustable positioning fixtures. These positioning devices can accurately determine the position and angle of the workpiece, and the error can be controlled within a very small range. For example, through high-precision positioning holes and matching positioning pins, precise positioning of the workpiece in the X, Y, and Z axis directions can be achieved, ensuring the positional accuracy of the welded joint and meeting the requirements of precision welding.

Stability and rigidity: In order to reduce the impact of worktable vibration or deformation on welding accuracy during the welding process, precision welding worktables have excellent stability and rigidity. The structural design has been optimized, and the frame is usually welded with high-strength steel and reinforced. At the same time, the support structure and connection parts of the workbench have been carefully designed and processed to withstand large loads and welding stresses, ensuring that the workbench remains stable during the welding process without deformation or displacement.

Environmental adaptability: In some situations where high requirements are placed on the welding environment, precision welding workbenches also have good environmental adaptability. For example, in fields such as electronics and aerospace, welding work needs to be carried out in a dust-free, constant temperature and humidity environment. The precision welding workbench can be equipped with corresponding protective devices and adjustment systems to adapt to different environmental conditions, ensuring that the welding quality is not affected by external factors.

Multi functional integration: Modern precision welding workbenches often integrate multiple functions to improve the efficiency and accuracy of welding work. In addition to basic positioning and support functions, automatic welding equipment interfaces, gas protection systems, lighting systems, etc. may also be equipped. For example, some precision welding workbenches are equipped with gas protection devices, which can provide stable protective gas during the welding process, prevent oxidation of the welding area, and improve welding quality; The lighting system can provide sufficient light, making it convenient for operators to observe the welding process and welding quality.

Application areas: Due to its high precision and multifunctional characteristics, precision welding workbenches are widely used in industries such as electronics, aerospace, medical equipment, and precision machinery manufacturing that require extremely high welding quality and accuracy. In the field of electronics, used for soldering small electronic components; In the aerospace industry, used for manufacturing and maintaining high-precision aviation components; In the field of medical devices, it is used for welding precision medical device components, etc.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province