Product Details

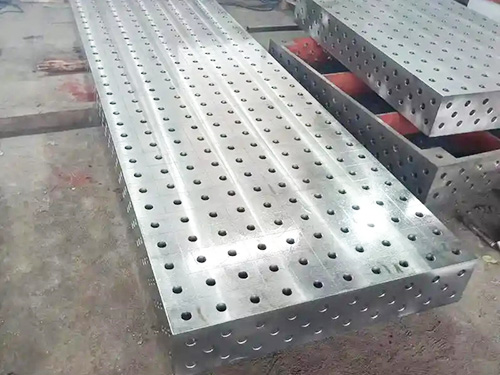

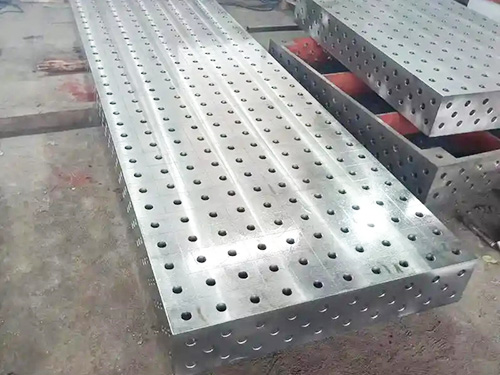

Quick Assembly Welding Table

A Quick Assembly Welding Table is a practical and efficient piece of equipment designed to simplify the setup process for welding operations.Here's a detailed introduction:

1.Key Features

Rapid Assembly Mechanism:The most distinctive feature of this type of welding table is its quick assembly system.It typically uses a combination of interlocking components,snap-fit connections,or simple bolt-and-nut arrangements that can be easily and quickly put together without the need for specialized tools or extensive technical knowledge.For example,some tables have pre-drilled holes and matching pins that allow different parts to be aligned and locked in place rapidly,enabling operators to set up the table in a matter of minutes.

Portability:Quick assembly welding tables are often designed with portability in mind.They are usually made from lightweight yet durable materials such as aluminum alloy or high-strength plastic composites.This reduces the overall weight of the table,making it easy to transport to different work locations.Additionally,some models may come with wheels or handles,further enhancing their mobility and allowing for convenient movement within a workshop or to an outdoor job site.

Modular Design:Many of these tables feature a modular structure,which means that different components can be added,removed,or replaced according to specific welding needs.For instance,the work surface can be customized with additional fixtures or accessories,and the legs or supports can be adjusted or swapped out to change the height or stability of the table.This modularity provides flexibility and allows the table to adapt to various welding tasks and work environments.

Sturdy Construction:Despite their ease of assembly and portability,quick assembly welding tables are built to be sturdy and stable.The materials used are carefully selected for their strength and durability,and the design is optimized to ensure that the table can withstand the rigors of welding operations.Reinforced joints and supports help to distribute the weight of the workpieces and the forces generated during welding,preventing any unwanted wobbling or instability.

2.Construction and Materials

Materials:

Aluminum Alloy:This is a popular choice for the frame and legs of quick assembly welding tables due to its lightweight nature and good corrosion resistance.Aluminum alloy also has sufficient strength to support the work surface and the weight of the workpieces during welding.

High-Strength Plastic Composites:Some tables may incorporate high-strength plastic composites for certain components,such as the tabletop or some of the modular parts.These materials offer excellent durability,are resistant to scratches and chemical damage,and can also reduce the overall weight of the table.

Steel Components:In some cases,steel may be used for critical parts that require greater strength,such as the load-bearing elements of the frame.Steel can provide the necessary stability and support for heavier welding tasks.

Construction:The construction of a quick assembly welding table involves precise manufacturing of the individual components to ensure a proper fit and easy assembly.The interlocking or connection points are designed to be strong and reliable,and the overall structure is often tested to ensure its stability and load-bearing capacity.The work surface is usually flat and smooth,and may be treated with a heat-resistant coating to protect it from the high temperatures generated during welding.

3.Applications

On-site Repairs and Maintenance:Quick assembly welding tables are ideal for on-site repair and maintenance work,such as in construction sites,factories,or industrial plants.Their portability and rapid assembly make it possible to quickly set up a working area wherever it is needed,allowing for efficient repair of equipment or structures.

Small-scale Fabrication and Prototyping:For small-scale fabrication businesses or hobbyists,these tables offer a convenient and cost-effective solution.The modular design and ease of assembly allow for quick setup and adjustment for different projects,and the portability makes it easy to store the table when not in use.

Outdoor Welding Projects:When working on outdoor welding projects,such as in agricultural settings,shipyards,or outdoor construction,a quick assembly welding table can be easily transported and set up.Its sturdy construction ensures that it can withstand the outdoor environment,and the rapid assembly feature saves time and effort compared to traditional,more complex welding tables.

4.Maintenance and Care

Regular Inspection:Periodically inspect the table for any signs of damage or wear,especially at the connection points and the work surface.Check for loose bolts,cracks,or any other issues that could affect the stability or performance of the table.

Cleaning:Keep the table clean by removing any welding debris,slag,or other contaminants after each use.Use a suitable cleaning solution and a soft cloth to wipe down the surface,taking care not to damage any coatings or finishes.

Lubrication:If the table has moving parts,such as wheels or adjustable legs,lubricate them regularly to ensure smooth operation.Use a lubricant recommended by the manufacturer to prevent rust and corrosion.

Storage:When not in use,store the table in a dry and protected area to prevent damage from moisture,dust,or other environmental factors.If the table is modular,disassemble it and store the components in a organized manner to make it easier to assemble the next time it is needed.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province