Product Details

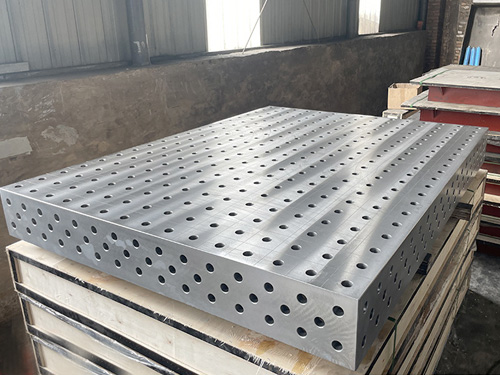

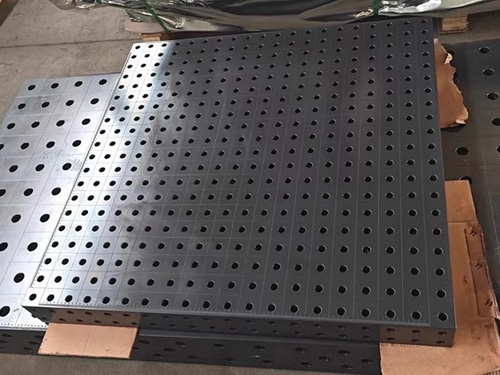

Reconfigurable Welding Table

A reconfigurable welding table is a highly adaptable and versatile piece of equipment in the field of welding,designed to meet the changing needs of different welding tasks.Here's a comprehensive look at its features,benefits,and applications:

Features

Modular Design:The core characteristic of a reconfigurable welding table is its modular construction.It consists of multiple interchangeable components,such as tabletop sections,legs,and fixtures.These modules can be easily assembled,disassembled,and rearranged.For example,the tabletop may be composed of individual panels that can be added or removed to adjust the overall size of the work surface.The legs can be different lengths or have adjustable height mechanisms,allowing for customization of the table's height.

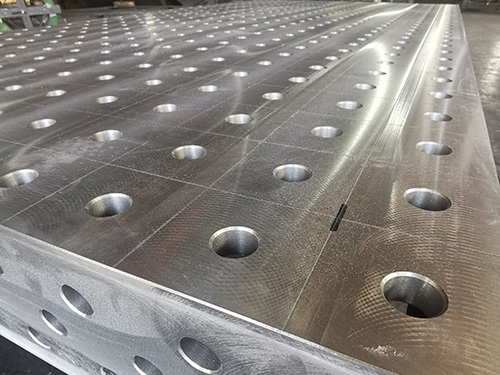

Quick-Connect Mechanisms:To facilitate the reconfiguration process,these tables often incorporate quick-connect or quick-release mechanisms.These can include snap-fit connectors,threaded joints that can be tightened or loosened rapidly,or magnetic connections.For instance,fixtures can be attached to the tabletop using magnetic bases that can be quickly positioned and detached as needed,reducing the time and effort required to change the setup.

Customizable Fixture System:The welding table comes with a wide range of customizable fixtures.These fixtures are designed to hold workpieces securely in place during welding.They can be adjusted in terms of position,orientation,and clamping force.Some fixtures may be adjustable along multiple axes,enabling precise positioning of complex workpieces.Additionally,the fixture system can be easily modified or replaced to accommodate different types of welding jobs.

Integrated Storage and Organization:Many reconfigurable welding tables feature integrated storage solutions.This can include drawers,shelves,or slots for holding welding tools,accessories,and small parts.Having these storage options built into the table helps keep the work area organized and ensures that everything needed for the welding process is within easy reach,improving workflow efficiency.

Benefits

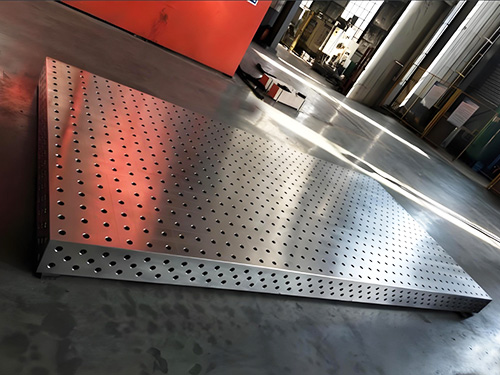

Increased Flexibility:The ability to reconfigure the table means it can be adapted to a diverse range of welding tasks.Whether it's working on small,intricate components or large,bulky structures,the table can be adjusted to provide the optimal setup.This flexibility reduces the need for multiple specialized welding tables,saving space and cost in the workshop.

Improved Productivity:With quick and easy reconfiguration,the time spent setting up for different welding jobs is significantly reduced.Workers can switch between tasks more efficiently,increasing overall productivity.The customizable fixture system also ensures that workpieces are held firmly and accurately,leading to higher quality welds and less rework.

Cost-Effectiveness:Instead of investing in multiple fixed-design welding tables for various applications,a single reconfigurable welding table can serve multiple purposes.Its modular nature allows for upgrades and modifications over time,extending its lifespan and reducing the long-term cost of equipment ownership.Additionally,the integrated storage helps prevent the loss of tools and accessories,further saving on replacement costs.

Enhanced Ergonomics:The adjustable height and customizable layout of the table can be tailored to the specific needs of the operator.This helps improve the ergonomics of the workspace,reducing the risk of fatigue and injury.For example,the table can be adjusted to a comfortable working height for standing or sitting operations,and the positioning of fixtures can be optimized to minimize awkward postures during welding.

Applications

Job Shops and Prototyping:In job shops that handle a wide variety of welding projects,a reconfigurable welding table is invaluable.It allows for quick adaptation to different customer requirements,whether it's prototyping a new product or fabricating custom-made components.The ability to change the table setup rapidly helps in meeting tight deadlines and providing a more responsive service to clients.

Automotive and Aerospace Manufacturing:These industries often require welding of different parts with varying geometries and specifications.A reconfigurable welding table can be used to assemble and weld components such as car frames,aircraft wings,and engine parts.Its precision and flexibility ensure that the high-quality standards of these industries are met.

Maintenance and Repair Work:In maintenance and repair applications,the reconfigurable table can be adjusted to fit the specific needs of the damaged or worn-out parts.It can be used to hold components in place during repair welding,making the process more efficient and accurate.For example,in the repair of heavy machinery,the table can be configured to support large and irregularly shaped parts.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province