Product Details

Welding Clamps and Fixtures

Welding clamps and fixtures are essential tools in the welding process,playing a crucial role in ensuring the quality and efficiency of welding operations.Here is a detailed introduction:

Welding Clamps

Function:Welding clamps are mainly used to hold and fix workpieces during welding.They can firmly clamp the workpieces to prevent movement or displacement during the welding process,ensuring the accuracy of the welding position and the quality of the weld.

Types:

Spring-type Clamps:These clamps use the elastic force of springs to generate clamping force.They are easy to operate and can quickly clamp workpieces.They are suitable for light-duty welding and situations where frequent clamping and releasing are required.

Screw-type Clamps:Screw-type clamps adjust the clamping force by rotating the screw.They can provide greater clamping force and are more stable,suitable for medium-and heavy-duty welding workpieces.

Magnetic Clamps:Magnetic clamps use the magnetic force of magnets to attract and fix workpieces.They are convenient to use and can be quickly adsorbed on the surface of ferromagnetic workpieces.However,their application is limited to ferromagnetic materials.

Welding Fixtures

Function:Welding fixtures are used to position and fix workpieces accurately,ensuring that the workpieces are in the correct position and posture during welding.They can also improve the efficiency of welding operations by facilitating the assembly and welding of workpieces.

Types:

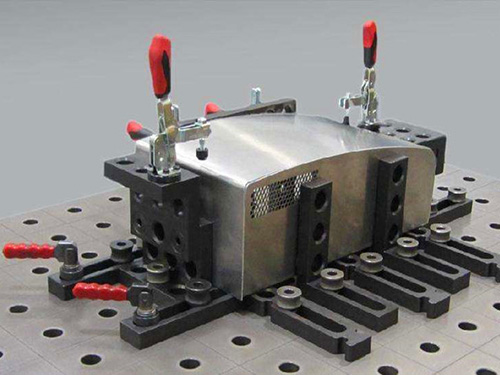

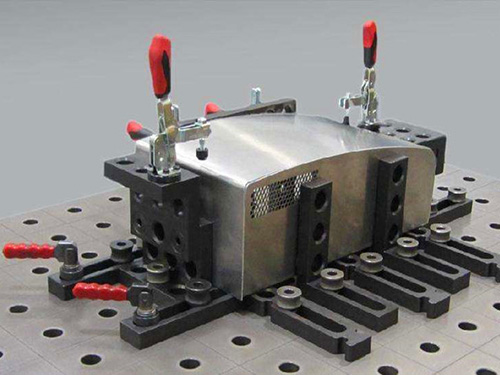

Universal Fixtures:Universal fixtures can be adjusted and adapted to different shapes and sizes of workpieces.They usually have adjustable components such as positioning pins,clamping blocks,and adjusting screws,which can be flexibly configured according to the specific requirements of the workpieces.

Special-purpose Fixtures:Special-purpose fixtures are designed and manufactured specifically for a certain type of workpiece or welding process.They have high positioning accuracy and efficiency and are suitable for mass-production welding.

Modular Fixtures:Modular fixtures are composed of standard modular components,which can be combined and assembled according to different welding requirements.They have the advantages of flexibility,reusability,and low cost.

In summary,welding clamps and fixtures are important tools in welding production.Choosing the appropriate type of clamp and fixture according to the specific requirements of the workpiece and the welding process can improve the quality and efficiency of welding and ensure the smooth progress of welding operations.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province