Product Details

Welding Clamps Table Imports Under HS Code 94039000

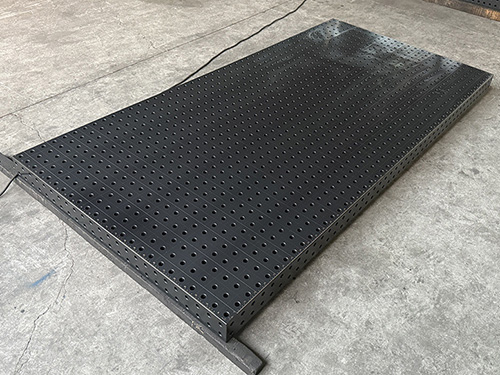

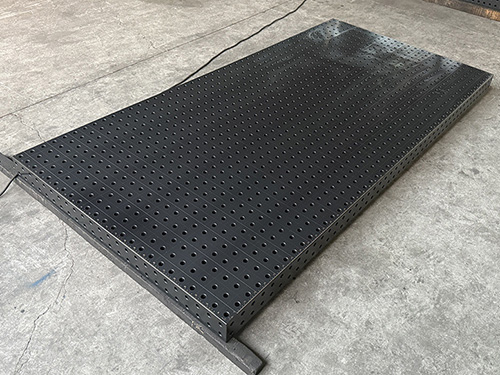

A welding clamps table is an essential piece of equipment in welding workshops.It is designed to hold and secure workpieces in place during the welding process,providing stability and precision.Here is a detailed introduction:

Structure and Design

Tabletop:Usually made of thick steel or cast iron,which can withstand high temperatures and heavy loads.The surface is often flat and smooth to ensure good contact between the workpiece and the table,and some tabletops may have grooves or holes for clamping and positioning.

Clamping Devices:There are various types of clamping devices installed on the table,such as mechanical clamps,magnetic clamps,and hydraulic clamps.These clamps can firmly hold the workpieces of different shapes and sizes,and adjust the clamping force according to the needs.

Frame:The frame of the welding clamps table is generally made of steel profiles,which has high strength and stability to support the weight of the tabletop and workpieces.Some frames may also be equipped with wheels or adjustable feet to facilitate the movement and leveling of the table.

Functions and Advantages

Improve Welding Quality:By firmly clamping the workpieces,the welding clamps table can prevent them from moving or vibrating during the welding process,which helps to ensure the accuracy and consistency of the welds and improve the welding quality.

Enhance Work Efficiency:The clamping devices on the table can quickly and easily fix the workpieces,saving the time and effort of manual positioning and clamping,and improving the work efficiency.At the same time,the reasonable design of the tabletop can also facilitate the operation of the welder,making the welding process more convenient and smooth.

Ensure Safety:The stable structure of the welding clamps table can prevent the workpieces from falling or tipping over during the welding process,reducing the risk of accidents and ensuring the safety of the operator.In addition,some clamping devices may also have safety locking mechanisms to further enhance the safety performance.

Applications

Metal Fabrication:Widely used in metal fabrication workshops,such as in the production of machinery parts,automotive components,and metal structures.It can help welders accurately position and weld various metal workpieces to meet the requirements of different products.

Repair and Maintenance:In the repair and maintenance of equipment and machinery,the welding clamps table is also an important tool.It can be used to fix the damaged parts and carry out welding repair operations to restore the performance and integrity of the equipment.

Artistic Welding:In the field of artistic welding,such as the creation of metal sculptures and handicrafts,the welding clamps table can provide a stable working platform for artists,helping them to complete complex welding works with high precision and creativity.

| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province