Product Details

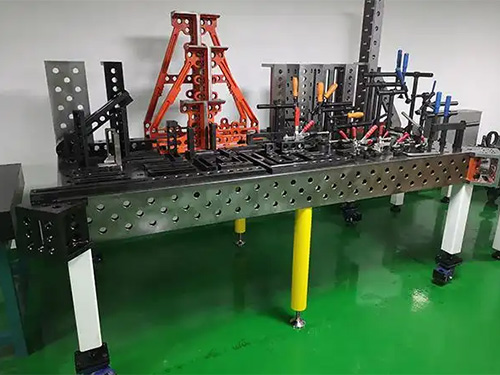

Welding Fixture Table

Welding Fixture Table:

Welding fixtures are important equipment used to fix workpieces, prevent deformation, and improve welding efficiency during the welding process. According to different classification standards, their types can be summarized as follows:

1、 Classified by purpose

Assembling Fixture

Used to fix various components of the workpiece before welding, complete spot welding or preliminary positioning, such as spot welding fixtures, clamping tools, tightening and pushing fixtures, etc.

Welding fixture

Complete all welding work on the basis of assembly fixtures, with a focus on controlling welding deformation, such as corner welding fixtures, right angle welding fixtures, C-shaped pliers, etc.

Special fixture

Designed for specific workpieces, it cannot be universally used, such as automotive dashboard welding fixtures, electric window welding fixtures, etc.

2、 Classified by power source

Manual clamp

Relying on human power to push the mechanism to clamp the workpiece, such as manual clamping tools, lever fixtures, etc.

pneumatic fixture

By driving the cylinder action with compressed air, the workpiece can be quickly clamped, making it suitable for large-scale production.

Electric fixture

By using electromagnetic force to clamp the workpiece, the angle and force can be adjusted to improve operational accuracy.

Hydraulic fixture

Clamping is achieved through hydraulic cylinder action, suitable for high load scenarios.

3、 Classified by structural form

Universal fixture 2

Multi directional adjustable, suitable for complex shaped workpieces.

Magnetic Fixture 2

Fixed by magnetic adsorption, suitable for welding magnetic materials.

Flexible fixture (universal fixture)

It can adapt to different workpieces without adjustment and has both assembly and welding functions.

4、 Other common types

Positioner: such as blocking iron, positioning pin, V-shaped iron, used for precise positioning.

Welding positioner: Adjust the angle of the welded component to optimize the welding effect.

summarize

The selection of welding fixtures should be based on process requirements, workpiece characteristics, and production scale. Assembly fixtures ensure positioning accuracy, welding fixtures ensure welding quality, and specialized fixtures enable process customization. Meanwhile, the matching of power sources (manual/pneumatic/electric) directly affects operational efficiency and safety.

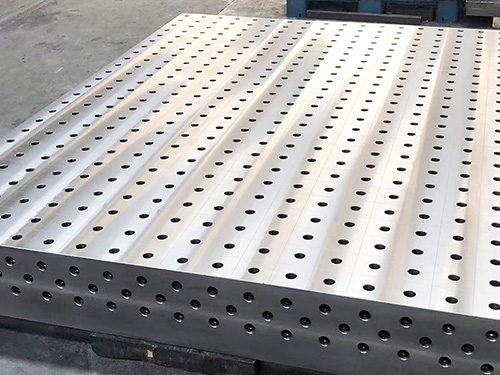

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province