Product Details

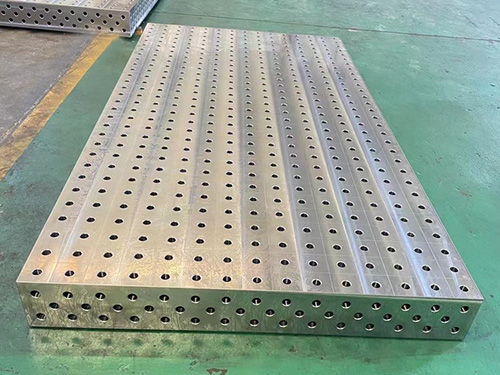

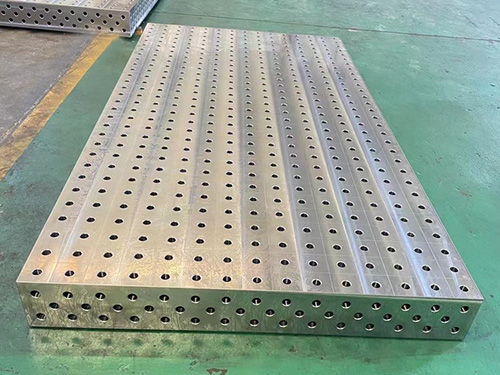

Welding Fixture Workbench

The three-dimensional flexible welding fixture has good bearing capacity and stable rigidity.Its five surfaces are machined with regular holes and engraved with mesh lines.The welding platform can be extended and combined conveniently.The expanded standard table can be directly connected with modular positioning and clamping.In the process of installing,adjusting and positioning the workpiece,the general functions of the three-dimensional flexible welding fixture and fixture system are displayed vividly and vividly in the application of large workpiece.The finish machining accuracy of the working surface of the three-dimensional flexible welding fixture is grade 0 and grade 1.The flat working surface shall be finished by scraping method or other process methods with similar effect to scraping method.

The surface of the cast iron platform shall be cleaned before commencement.The residual gravel and burrs left after processing will affect the measurement accuracy,and the platform will rust due to moisture or other reasons.Therefore,the oil and rust parts shall be brushed off with steel wire,and the sharp edges shall be trimmed.The cast iron platform has good performance and micro quality.Generally speaking,if the flatness of the surface reaches the standard,the service life will be extended.In addition,improper operation and other external reasons may lead to local deformation of the platform surface,which will seriously affect the measurement accuracy.Therefore,regular inspection should be carried out.Once problems are found,they should be solved in time to avoid delaying the overall work.The common benchmark tool for marking and detecting workpieces in industry is the cast iron platform.Before putting into use,the cast iron platform should be strictly treated,which has a great impact on its own quality and work quality.There are technical indicators for the production of cast iron platform.The technical indicators are used in the inspection of cast iron platform,which usually need to be checked in two aspects.

The working surface of the welding fixture workbench adopts the scraping process,and the working surface can be processed with V-shaped,T-shaped,U-shaped grooves,round holes,long holes,etc.Specification of welding platform:special specifications can be designed and produced according to user requirements.Green casting is divided into resin sand casting and cement sand casting.Now large iron castings generally use these two molding methods,both of which are lost foam casting.Generally,large batches of castings with small proportion are cast in wood mold.Resin sand casting is mainly used for large machine tool castings and related welding platforms.The price is higher than that of cement sand casting.80%of the welding platforms are cast in cement sand casting,which can not only meet the requirements of the technical parameters of the welding platform,but also reduce the manufacturing cost of the welding platform.

What accessories are required for the working surface support of the welding fixture workbench?Now let me give you a detailed introduction:

1、Locking part:the quick locking part is one of the flexible modular fixture products.It is easy to disassemble and acts on the quick loading and unloading and locking handle type locking pin countersunk head locking pin magnetic locking pin.

2、Positioning piece:positioning angle ruler can accurately position or height positioning ruler/plane angle ruler can accurately adjust the positioning position.V-shaped positioning piece positioningφ60/angle 90-150.

3、Hold down part:fixed fast hold down part,retractable hold down part,45 degree hold down part.

4、Brace:the supporting angle iron is used to accurately locate or assist the pressing parts of accessories and the supporting U-shaped/l-shaped square box is used to locate the height or expand the width and the supporting or pressing angle connecting block of other accessories 90 degrees right angle connection module.

5、Accessories:tool trolley,grounding device,lifting ring,nylon brush,Allen wrench,oilstone,oil pot,etc.

6、Adjusting parts:adjusting shims and height adjusters are mainly used to pad the positioning size of the workpiece.The angler can accurately position any angle of 0-225 degrees according to the scale.

7、Support type of worktable:support type platform bearing capacity standard type 2T belt brake universal wheel type 1t fixable type 2T frame structure type 5T hydraulic lifting type 3T.

The material of welding fixture workbench is generally HT200 or HT250,which can meet the requirements of welding workpiece,and the tensile resistance,hardness and degree of welding platform can meet the welding requirements.If you want to know the accuracy of the welding fixture workbench,you need to carry out inspection,and inspection instruments are needed.The purchase of electronic level is more accurate today.Install and adjust the level of the platform,place the electronic level on the welding platform for intercept method inspection,record according to the inspection data,and then input it into the level software for calculation.The value obtained is the error value of the flatness of the welding platform!

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province