Product Details

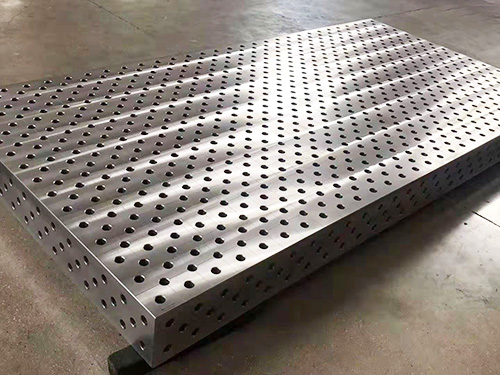

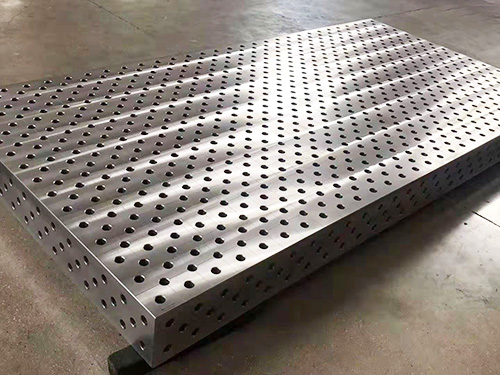

Welding Positioning Table

A welding positioning table is a crucial device in welding operations,designed to accurately position and hold workpieces during the welding process.Here is a detailed introduction:

Structure

Tabletop:It is usually made of high-strength and wear-resistant materials such as steel.The surface is precisely machined to be flat and smooth to ensure the stability of workpiece placement.Similar to the D welding table mentioned before,there are often grids of holes or T-slots on the tabletop.The holes are of a specific diameter,like 16mm or 28mm,and are arranged at regular intervals,usually 50mm or 100mm apart.The T-slots are used for installing various positioning and clamping devices.

Support System:The tabletop is supported by a rigid frame structure.This structure is engineered to bear the weight of the workpieces and the forces generated during welding without undergoing significant deformation.The legs of the support system are often adjustable in height to enable the tabletop to be leveled on different floor surfaces.Some advanced models might be equipped with shock-absorbing mechanisms to minimize the impact of vibrations on the welding process.

Working Principles

Positioning:The grid-like holes and T-slots on the tabletop serve as the fundamental positioning references.Special positioning pins or fixtures are inserted into these holes or slots to precisely locate the workpieces in the X,Y,and Z axes.This ensures that the workpieces are accurately positioned relative to each other before welding,reducing errors and ensuring the accuracy of the weld joints.For example,in the production of complex metal structures,multiple components need to be precisely aligned,and the positioning table plays a vital role in achieving this.

Clamping:A variety of clamping devices,including clamps,bolts,and nuts,are used in combination with the holes and T-slots to firmly secure the workpieces to the tabletop.This prevents the workpieces from moving or vibrating during the welding process due to the heat and force generated.By maintaining the stability of the workpieces,the quality of the welds is improved.For instance,when welding large-scale metal parts,the clamping mechanism ensures that the parts remain in position,preventing misalignment and ensuring a high-quality weld.

Applications

Automotive Manufacturing:In the automotive industry,welding positioning tables are widely used in the production of car bodies.They are used to position and weld various components such as car frames,doors,and hoods.The high-precision positioning provided by these tables ensures the dimensional accuracy and quality of the car body,meeting the strict requirements of the automotive industry.

Aerospace Industry:For the manufacturing of aircraft components,welding positioning tables are essential.They are used to weld complex and high-precision aerospace parts,ensuring the dimensional accuracy and structural strength of the components meet the stringent standards of the aerospace industry.The ability to precisely position and hold the workpieces is crucial for the integrity of the aircraft structures.

General Machinery Manufacturing:In the production of general machinery,such as machine tools,industrial equipment,and agricultural machinery,welding positioning tables are used to weld various components.They help improve the manufacturing accuracy and quality of the machinery,ensuring the proper fit and function of the welded parts.

Metal Fabrication and Construction:In metal fabrication workshops and construction sites,welding positioning tables are used for tasks such as welding metal frames,staircases,and structural components.They provide a stable and precise platform for welding,facilitating the production of high-quality metal products and ensuring the structural integrity of the constructed elements.

Advantages

High Precision:The precise machining of the tabletop and the use of standardized positioning and clamping elements enable high-precision workpiece positioning.This is essential for achieving high-quality welds with accurate dimensions and good appearance,especially in applications where tight tolerances are required.

Increased Productivity:By simplifying and accelerating the processes of workpiece positioning and clamping,welding positioning tables reduce the setup time for welding operations.This leads to increased productivity as more welding tasks can be completed in a given time.The efficient use of time and resources is beneficial for large-scale production environments.

Versatility:These tables are often designed to be versatile,capable of accommodating workpieces of different shapes,sizes,and weights.The adjustable features,such as movable clamping blocks and angle-setting devices,allow for easy adaptation to various welding requirements.This versatility makes the welding positioning table a valuable asset in different manufacturing and fabrication processes.

Improved Quality Control:The stable clamping and accurate positioning of workpieces provided by the welding positioning table contribute to better quality control.Consistent positioning and reduced workpiece movement during welding result in more uniform welds and fewer defects.This helps to improve the overall quality of the welded products and reduces the need for rework or repairs.

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province