Product Details

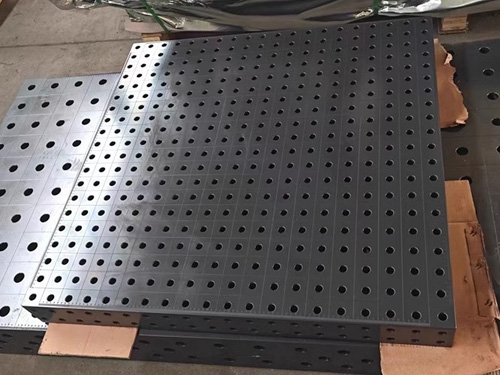

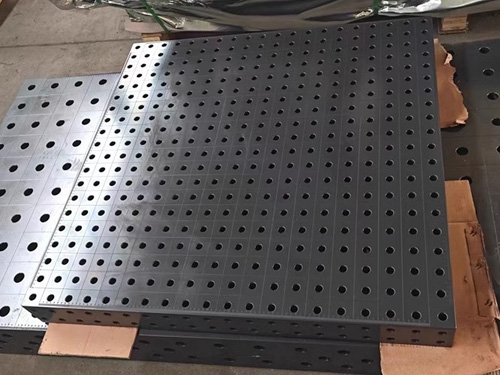

Welding Table for Metal Fabrication

In the field of metal processing, every weld seam is related to the quality and performance of the product. Our metal processing welding table is designed to meet the high-strength and high-precision metal processing needs, making it an ideal choice for promoting production efficiency and quality upgrades.

Excellent structure, capable of carrying heavy operations

The metal processing welding table is made of high-strength alloy steel as the main material, and is constructed through precision welding and heat treatment processes. The sturdy frame structure and thickened tabletop design give it strong load-bearing capacity, making it easy to withstand metal workpieces weighing several tons. It maintains stability during heavy metal structure welding, large mechanical component assembly, and other operations, effectively avoiding welding accuracy affected by tabletop deformation. At the same time, scientific mechanical structure design ensures that the welding table can maintain reliable performance even under heavy pressure and welding stress, providing solid support for complex metal processing tasks.

Accurate positioning ensures welding accuracy

The countertop is equipped with a high-precision T-shaped groove and grid positioning system, with precise spacing and uniform size between the T-shaped grooves. It can quickly install various fixtures, positioning pins, and other auxiliary tools to achieve precise fixation and multi angle positioning of the workpiece; The grid positioning system assists operators in quickly calibrating the position of the workpiece with clear scales, with a positioning accuracy of ± 0.1mm, effectively reducing manual measurement errors. Whether it is welding regular shaped metal plates or splicing irregular workpieces, it can ensure the accuracy of welding positions, improve the qualification rate of finished products, and meet the strict requirements for welding accuracy in high-end industries such as aerospace and automotive manufacturing.

Flexible adaptation to meet diverse needs

The metal processing welding table supports modular design, which can be freely combined to expand the worktable or add or remove functional modules according to different processing tasks and workpiece sizes. For example, adding a rotating workbench module to achieve 360 degree rotation welding of workpieces; Equipped with a dedicated welding power interface and cable management system, it facilitates the connection and wiring organization of various welding equipment. This high degree of flexibility makes it widely applicable in various fields such as metal furniture manufacturing, steel structure processing, and mold welding, making it easy to meet diverse production needs.

Durable and easy to maintain, reducing usage costs

The surface of the welding table has been specially treated to have excellent wear resistance, corrosion resistance, and high temperature resistance, which can resist the erosion of welding sparks and metal debris, reduce table wear and scratches, and extend the service life of the equipment. At the same time, the simple structural design and standardized components facilitate daily cleaning, maintenance, and troubleshooting. Even if there is partial damage, it can be quickly replaced and repaired, effectively reducing downtime and maintenance costs, and providing strong support for the sustained and stable production of enterprises.

Choosing our metal processing and welding station means choosing to empower metal processing with professional equipment, providing precise, efficient, and durable quality to help enterprises stand out in fierce market competition!

performance parameter:| D28 Welding Table Quotation List | |||||||

| specifications ( mm) | leg of a table | weight (kg) | Material model | ||||

| 1000*800*200 | 4 | 240 | 2D D28 SteelSeries |

3D D28 Cast Iron Series |

3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*200 | 4 | 280 | |||||

| 1200*800*200 | 4 | 280 | |||||

| 1200*1000*200 | 4 | 330 | |||||

| 1200*1200*200 | 4 | 380 | |||||

| 1500*1000*200 | 4 | 380 | |||||

| 1500*1500*200 | 4 | 600 | |||||

| 2000*1000*200 | 4 | 500 | |||||

| 2000*1500*200 | 4 | 750 | |||||

| 2000*2000*200 | 5 | 1100 | |||||

| 2400*1200*200 | 6 | 750 | |||||

| 2500*1500*200 | 6 | 950 | |||||

| 2500*2000*200 | 8 | 1250 | |||||

| 3000*1000*200 | 6 | 800 | |||||

| 3000*1500*200 | 6 | 1100 | |||||

| 3000*2000*200 | 8 | 1500 | |||||

| 3000*2500*200 | 8 | 2000 | |||||

| 3000*3000*200 | 10 | 2500 | |||||

| 4000*1000*200 | 6 | 1100 | |||||

| 4000*2000*200 | 8 | 2100 | |||||

| 5000*2000*200 | 10 | 2700 | |||||

| 6000*2000*200 | 14 | 3500 | |||||

| D16 Welding Table Quotation List | |||||||

| Material model | |||||||

| specifications ( mm) | leg of a table | weight (kg) | 2D Steel Series | 3D Cast Iron Series | 3D cast ironnitriding series | 3D Steel Series | 3D Steel Nitriding Series |

| 1000*1000*150 | 4 | 200 | |||||

| 1200*1000*150 | 4 | 250 | |||||

| 1500*1000*150 | 4 | 300 | |||||

| 2000*1000*150 | 6 | 400 | |||||

| 2400*1200*150 | 6 | 500 | |||||

| 3000*1500*150 | 6 | 800 | |||||

HOT NEWS

HOT NEWS

-

How to Maintain Granite Platforms in Dusty Environments

2025-11-24 02:03:22

-

Modular Welding Tables: Boosting Accuracy and Efficiency in Fabrication

2025-11-21 12:25:54

-

Comprehensive Guide to Surface Treatment for Cast Iron Platforms

2025-11-18 12:25:34

-

Best Welding Table Options for Small Workshops

2025-11-15 10:33:25

-

Flexible Welding Tooling Solutions from China Manufacturer

2025-11-12 09:40:09

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province