News Detail

Best Practices for Cleaning T-Slot Cast Iron Platforms

author:hxrtools Time:2026-01-27 21:35:23 Click:108

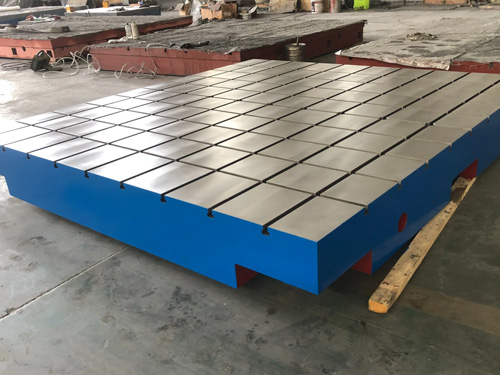

The Manufacturing Importance of T-Slot Cast Iron Platforms

In modern machining and assembly environments, the T-slot Cast Iron Platform plays a crucial role in supporting fixtures, workpieces, and precision equipment. Its combination of strength, rigidity, and flexibility makes it a standard solution in workshops, inspection areas, and industrial production lines.

From the standpoint of a professional T-slot Cast Iron Platform manufacturer, consistent production quality and the ability to support batch supply are essential. Proper cleaning and maintenance directly affect platform accuracy, service life, and overall production efficiency.

Understanding the Structure of T-Slot Cast Iron Platforms

A T-slot cast iron platform is designed with precisely machined slots that allow flexible positioning of clamps, fixtures, and tooling. These slots are essential for modular setups but also tend to accumulate chips, oil, dust, and coolant residues.

Without regular cleaning, contaminants can compromise flatness, interfere with fixturing accuracy, and accelerate surface wear.

Why Proper Cleaning Matters

Preserving Accuracy and Flatness

Precision machining relies on accurate reference surfaces. Even small debris trapped in T-slots can affect workpiece positioning and measurement results. Regular cleaning helps maintain surface flatness and ensures consistent machining outcomes.

Manufacturers with large-scale production experience emphasize preventive maintenance to protect the long-term accuracy of platforms delivered in batch quantities.

Preventing Corrosion and Surface Damage

Cast iron is durable, but exposure to moisture, cutting fluids, and chemical residues can lead to corrosion if not properly managed. Cleaning removes corrosive agents and allows protective treatments to function effectively.

Recommended Cleaning Tools and Materials

Non-Abrasive Cleaning Tools

Use soft brushes, lint-free cloths, or compressed air to remove loose debris from the platform surface and T-slots. Avoid abrasive pads or metal tools that can scratch or damage the machined surface.

Suitable Cleaning Agents

Neutral or mildly alkaline cleaners are recommended for cast iron platforms. Strong acids or aggressive solvents should be avoided, as they can attack the surface and reduce the platform’s service life.

Step-by-Step Cleaning Process

Step 1: Remove Loose Contaminants

Begin by brushing or blowing away chips, dust, and loose particles from the surface and inside the T-slots. This prevents debris from being dragged across the platform during wet cleaning.

Step 2: Surface Wiping

Use a slightly damp, lint-free cloth with a suitable cleaning agent to wipe the platform surface. Pay attention to areas around the T-slots where residues tend to accumulate.

Step 3: T-Slot Detailing

For deeper cleaning of T-slots, narrow brushes or specialized slot-cleaning tools can be used. Ensure all contaminants are removed from the slot base and edges.

Manufacturers often recommend periodic deep cleaning, especially in high-volume production environments.

Step 4: Drying and Inspection

After cleaning, thoroughly dry the platform to prevent moisture retention. Inspect the surface and slots for signs of wear, corrosion, or damage that may require corrective action.

Protective Measures After Cleaning

Applying Protective Coatings

Light application of rust-preventive oil or protective coatings helps safeguard the cast iron surface against humidity and corrosion. This is particularly important in facilities with fluctuating environmental conditions.

Environmental Control

Maintaining a clean and stable workshop environment reduces contamination and extends the interval between cleaning cycles. Platforms produced under controlled manufacturing standards perform best when supported by proper environmental management.

Cleaning Frequency Recommendations

The optimal cleaning frequency depends on usage intensity and operating conditions:

·Daily: Light cleaning in high-use machining areas

·Weekly: Thorough cleaning of T-slots and surface

·Monthly: Inspection and reapplication of protective coatings

Facilities using multiple platforms from the same production batch benefit from standardized cleaning schedules.

Common Cleaning Mistakes to Avoid

·Using abrasive tools or harsh chemicals

·Allowing moisture to remain on the surface

·Ignoring T-slot interiors

·Skipping routine inspections

Avoiding these mistakes helps preserve platform accuracy and extends its operational lifespan.

Long-Term Maintenance and Production Efficiency

Proper cleaning is a key part of long-term maintenance strategy. Well-maintained T-slot cast iron platforms contribute to consistent machining accuracy, reduced downtime, and lower replacement costs.

From a manufacturing perspective, platforms produced with controlled casting and machining processes offer better resistance to wear and easier maintenance over time.

Conclusion: Clean Platforms, Consistent Performance

The T-slot Cast Iron Platform is a foundational component in precision machining and assembly operations. Following best practices for cleaning ensures that these platforms continue to deliver accuracy, durability, and reliability.

For industrial users, sourcing platforms from an experienced T-slot Cast Iron Platform manufacturer with proven production capacity and batch supply capability provides confidence in long-term performance. Combined with proper cleaning and maintenance, high-quality platforms remain a dependable asset in modern manufacturing environments.

References

GB/T 7714:Slocum A H. Precision machine design[M]. Society of Manufacturing Engineers, 1992.

MLA:Slocum, Alexander H. Precision machine design. Society of Manufacturing Engineers, 1992.

APA:Slocum, A. H. (1992). Precision machine design. Society of Manufacturing Engineers.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province