News Detail

CNC Welding Platforms: Where Automation Meets Accuracy

author:hxrtools Time:2026-01-24 21:24:14 Click:144

CNC Welding Platforms in Modern Manufacturing

As manufacturing processes continue to evolve toward higher efficiency and automation, welding operations are no longer limited to manual setups. The CNC welding platform has become a critical foundation where automation meets accuracy, enabling manufacturers to achieve repeatable, high-quality welding results.

From the perspective of a professional CNC welding platform manufacturer, stable production processes, strict quality control, and the ability to support batch supply are essential. High-performance welding platforms play a vital role in automated welding cells, robotic production lines, and precision fabrication environments across multiple industries.

What Is a CNC Welding Platform?

A CNC welding platform is a precision-engineered base used to support automated and semi-automated welding systems. It provides a flat, rigid, and accurately machined surface that ensures consistent positioning of workpieces during welding operations.

These platforms are commonly integrated with:

·CNC-controlled welding systems

·Robotic welding arms

·Automated fixture and clamping systems

·Large-scale fabrication lines

The platform serves as the reference surface that directly affects welding accuracy and repeatability.

The Role of Automation in Welding Accuracy

Consistent Positioning and Repeatability

Automation demands consistency. A CNC welding platform ensures that each workpiece is positioned exactly as programmed, reducing variation between weld cycles. This consistency is essential for achieving uniform weld penetration, bead appearance, and structural integrity.

Manufacturers with advanced production capabilities focus on surface flatness and dimensional accuracy to meet the requirements of automated welding systems.

Structural Stability Under Welding Loads

Resistance to Thermal and Mechanical Stress

Welding processes generate significant heat and mechanical stress. A high-quality CNC welding platform is designed to withstand repeated thermal cycles without deformation. Its structural rigidity prevents distortion, ensuring that weld geometry remains accurate throughout production.

From a production standpoint, platforms manufactured through controlled machining and inspection processes deliver reliable performance even under continuous industrial use.

Precision Machining for Automated Welding Systems

Flatness and Tolerance Control

Precision is the foundation of automated welding. CNC welding platforms are typically machined to tight tolerances, allowing them to serve as accurate reference planes for fixtures, clamps, and robotic tooling.

For large production facilities, sourcing platforms from a single manufacturer with batch supply capability helps maintain uniformity across multiple welding stations.

Integration With Modular Fixturing Systems

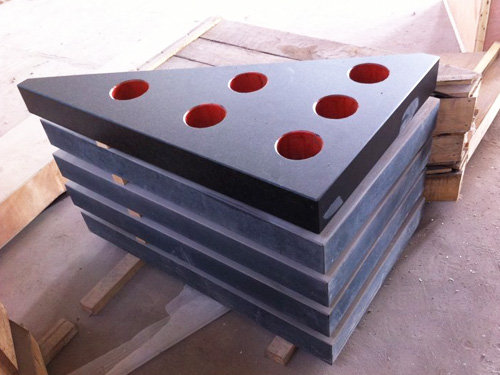

Modern CNC welding platforms are often designed to work with modular fixturing systems. Features such as grid patterns, threaded holes, or T-slots allow flexible fixture arrangements without compromising accuracy.

This adaptability supports quick changeovers and reduces downtime, making CNC welding platforms suitable for both mass production and customized fabrication.

Improved Productivity and Reduced Rework

Automation-Driven Efficiency

By combining a CNC welding platform with automated control systems, manufacturers can significantly increase throughput while minimizing human error. Accurate positioning reduces misalignment-related defects, leading to lower rework rates and improved overall efficiency.

In high-volume production environments, this translates directly into cost savings and predictable output.

Applications Across Industries

CNC welding platforms are widely used in industries that demand high precision and repeatability, including:

·Automotive manufacturing

·Heavy machinery fabrication

·Structural steel production

·Energy and power equipment

·Aerospace component welding

Their versatility and durability make them an essential component of modern automated welding systems.

Manufacturing Quality: Why the Platform Matters

The performance of a CNC welding platform depends heavily on its manufacturing process. Key production stages include:

1.Material selection and preparation

2.Precision machining and surface finishing

3.Stress relief or stabilization treatment

4.Dimensional inspection and quality verification

Manufacturers with standardized production processes and experience in batch supply are better equipped to deliver consistent platform quality for automated welding applications.

Maintenance and Long-Term Performance

Although CNC welding platforms are designed for durability, proper maintenance ensures long-term accuracy. Regular cleaning, inspection of mounting points, and periodic verification of flatness help preserve performance over extended production cycles.

Platforms produced by experienced manufacturers typically maintain their accuracy longer due to controlled material processing and machining practices.

Future Trends in CNC Welding Platforms

As automation and Industry 4.0 technologies advance, CNC welding platforms are evolving to support smarter manufacturing environments. Integration with sensors, digital alignment systems, and adaptive fixturing is becoming increasingly common.

These developments further strengthen the role of CNC welding platforms as a critical interface between automated equipment and precision manufacturing.

Conclusion: The Foundation of Automated Welding Accuracy

The CNC welding platform is more than a supporting surface—it is the foundation that enables automation, accuracy, and efficiency in modern welding operations. Its ability to provide stability, precision, and repeatability makes it indispensable in automated and robotic welding systems.

For manufacturers seeking reliable performance, working with an experienced CNC welding platform manufacturer that emphasizes controlled production processes and batch supply capability ensures consistent quality across all welding stations. As automation continues to shape the future of manufacturing, CNC welding platforms will remain at the center of accurate and efficient welding solutions.

References

GB/T 7714:Koenigsberger F, Tlusty J. Machine tool structures[M]. Elsevier, 2016.

MLA:Koenigsberger, Franz, and Jiri Tlusty. Machine tool structures. Elsevier, 2016.

APA:Koenigsberger, F., & Tlusty, J. (2016). Machine tool structures. Elsevier.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province