News Detail

Welding Table Height Design: What is the Golden Ergonomic Height?

author:hxrtools Time:2025-07-11 11:59:57 Click:108

In welding operations, the height design of the workbench is not only related to the comfort of the operators but also directly impacts the welding quality and production efficiency. A welding table that meets ergonomic height standards can significantly reduce operator fatigue, improve work efficiency, and reduce the risk of occupational diseases caused by prolonged improper postures. So, what is the golden height design for a welding table?

I. Ergonomic Principles and Welding Table Height Design

Ergonomics is the science of optimizing the interaction between people and machines to make work, study, and life more comfortable and efficient. The application of ergonomic principles in welding table height design is crucial.

According to ergonomic principles, the optimal working height of the table should be around the level of the operator’s elbow joint. This design ensures that operators can maintain a natural posture during welding, reducing pressure on the neck, shoulders, and back, thus minimizing fatigue. Specifically, when operators stand while welding, the welding table height should be slightly above their elbow level to allow the arms to hang naturally, reducing muscle strain.

II. Welding Table Height Recommendations for Different Welding Tasks

1. Light Welding Tasks

For tasks involving objects weighing less than 1kg, such as jewelry making or small electronic product welding, the welding table height is generally designed between 800mm and 950mm. This height range can meet the needs of operators working both standing or sitting, while keeping the arms in a natural hanging position to reduce fatigue.

2. Medium Welding Tasks

For tasks involving objects weighing between 1kg and 4.5kg, such as mechanical part welding and pipe welding, the welding table height should be slightly higher than the operator’s elbow height, typically between 860mm and 940mm. This height range ensures that operators maintain a stable posture during welding while minimizing muscle fatigue caused by the weight of the parts.

3. Heavy Welding Tasks

For tasks involving objects weighing over 4.5kg, such as large steel structure welding or shipbuilding, the welding table height should be lower, typically between 500mm and 860mm. A lower welding table height helps increase stability and reduce fatigue in the lower back and legs caused by long periods of standing or handling heavy items.

III. International Standards and Guidelines for Welding Table Height Design

Internationally, there are standards and guidelines that govern the design of workbenches. For example, the International Organization for Standardization (ISO) has published related standards that set specific requirements for the height, depth, and width of welding tables. These standards aim to ensure that welding table designs are ergonomic, improving both comfort and work efficiency.

Additionally, several countries and regions have developed more detailed guidelines for welding table height design. These guidelines are usually based on local body size data, work tasks, and working environment conditions, providing more specific reference points for welding table height design.

IV. Practical Examples and Experience Sharing

In practice, many companies have already optimized the design of their welding tables based on ergonomic principles and international standards. For example, a well-known automotive manufacturer adjusted the height and angle of their welding tables to ensure that operators maintain a natural posture during welding, significantly reducing fatigue and increasing productivity. Furthermore, the company introduced adjustable-height welding tables to accommodate operators of different heights and task requirements.

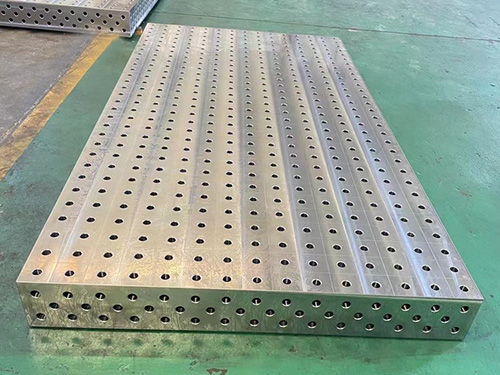

V. Our Welding Tables: A Model of Ergonomic Design

As a professional manufacturer of welding tables, we understand the importance of ergonomic design in welding operations. Our welding tables are designed with ergonomic principles in mind, ensuring operators maintain a comfortable posture during work. We also offer a variety of height adjustment options to accommodate operators with different heights and work requirements.

Additionally, our welding tables are built with high-strength, high-stability materials to meet the needs of various welding tasks. Whether for light, medium, or heavy welding tasks, our welding tables provide stable and reliable support.

VI. References

·ISO (International Organization for Standardization): ISO has released multiple standards related to welding table design, such as the ISO 9241 series, which provides universal specifications for welding table height, depth, and width.

·ASME (American Society of Mechanical Engineers): ASME has released several standards regarding the design, manufacturing, and testing of welding equipment, ensuring the performance and quality of welding tables.

·TÜV (Technical Inspection Association): TÜV has published reports on the safety and ergonomic design of welding tables, analyzing key parameters such as height, angle, and stability, and providing scientific evidence for optimal welding table design.

By understanding the ergonomic principles and designing welding tables accordingly, it is possible to significantly improve work efficiency, reduce fatigue, and enhance operational safety. If you have any related needs, please feel free to contact our technical support team. We are committed to providing high-quality, tailored welding tables for your needs.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province