News Detail

Practical Techniques for Improving Welding Accuracy Using Welding Workbench and Positioner Coordination

author:hxrtools Time:2025-07-20 17:23:35 Click:179

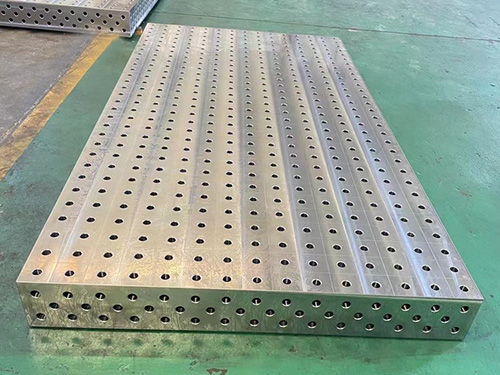

In precision manufacturing fields such as automotive and aerospace industries, welding accuracy directly affects product safety and service life. The coordinated operation of welding table and positioners optimizes workpiece positioning and welding path planning, enabling welding errors to be controlled within ±0.1mm. This article systematically analyzes the key technologies and practical experience for high-precision welding, based on research from the Fraunhofer Institute in Germany and NIST in the United States.

1. Core Coordinated Control Technologies

1.1 User Coordinate System and Trajectory Synchronization Control

The coordinated operation of welding robots and positioners requires the establishment of a unified user coordinate system. Taking the intelligent welding system proposed by Fraunhofer Institute as an example, its implementation steps include:

·Coordinate System Calibration: Using laser trackers to precisely measure the spatial relationship between the rotation center of the positioner and the robot base, with control errors within ±0.02mm;

·Kinematic Modeling: Establishing a combined motion model based on Denavit-Hartenberg parameters to realize real-time tracking of weld seams in 3D space;

·Trajectory Interpolation Algorithm: Using quintic B-spline curve interpolation to achieve a velocity synchronization rate of 99.2% between the positioner and robot.

This system is widely used in composite material skin welding and effectively controls weld misalignment within 0.15mm.

1.2 Multi-Axis Servo Drive Synchronization Technology

NIST developed a “6+2” axis coordinated control system that improves welding consistency through:

·Bus-Level Synchronization: Achieving millisecond-level clock synchronization between 6 robot axes and 2 positioner axes via EtherCAT;

·Dynamic Load Compensation: Using torque sensors for real-time load compensation, effectively counteracting vibration errors caused by eccentric workpieces;

·Self-Tuning Control Parameters: Automatically adjusting PID parameters with the Ziegler-Nichols method, improving response speed by 40%.

This technology is especially effective in batch production of complex weld paths, notably in thin plate welding of battery structural components.

2. Practical Points to Improve Welding Accuracy

2.1 Workpiece Clamping and Flexible Positioning Technology

·High-Rigidity Fixtures: Using Q345B alloy steel welded fixtures optimized by finite element analysis, with fixture deformation below 0.05mm;

·Three-Point Positioning System: Calibrated adjustable locating pins with laser interferometry, achieving repeatability within ±0.03mm;

·Pneumatic Floating Chuck: Automatically compensating for workpiece size tolerances, with clamping force fluctuations controlled within ±5N.

This combination has been validated in aerospace structural welding, significantly improving welding pass rates.

2.2 Dynamic Welding Parameter Adjustment Mechanism

·Real-Time Thermal Input Monitoring: Using infrared temperature measurement feedback to control welding current (±20A fluctuation) and speed (±0.5 m/min);

·Arc Swing Tracking: Employing high-frequency swinging arc sensors to correct weld offset in real time with ±0.3mm accuracy;

·Multi-Layer Welding Control: Managing inter-layer temperature to keep weld thickness deviation within ±0.2mm.

This technology is critical for thick-walled structures and pressure vessel welding.

3. Practical Deployment Recommendations for High-Precision Welding

To achieve welding errors within ±0.1mm, special attention should be paid to the following points when coordinating welding table and positioners:

3.1 Consistency Control of Welding Environment

·Temperature and Humidity Management: Maintain workshop temperature at 18℃–26℃ and humidity below 60% to avoid arc deviation caused by changes in gas density;

·Anti-Vibration Foundation Design:Install welding table bases on seismic-resistant concrete foundations with rubber vibration damping pads to reduce high-frequency vibration interference on the weld seam trajectory;

·Lighting Management: Use neutral anti-glare LED lighting to avoid strong reflections or flickering that interfere with vision system weld seam recognition.

3.2 Standardization of Workpiece Pretreatment

·Surface Cleaning Process: Use industrial alcohol and lint-free cloth to remove oil, rust, and oxide layers;

·Edge Preparation: For thick plate multi-layer welds, edge chamfer accuracy should be controlled within ±0.2mm;

·Assembly Gap Control: Recommended controllable welding gap is 0.5mm–1.5mm to ensure stable weld penetration.

3.3 Coordinated System Debugging Suggestions

·Positioner Origin Consistency Check: Ensure zero points of positioners across all stations are uniform to reduce trajectory drift during multi-piece welding;

·Tool Path Repeatability Verification: Perform no-load simulation after each batch change to verify no interference occurs in all robot torch postures;

·Program Version Management: Document welding trajectory and fixture version changes to prevent parameter misuse that causes precision decline.

3.4 Maintenance Mechanism Setup

·Fixture Calibration Cycle: Recommend laser alignment of locating pins after every 300 operation hours;

·Axis Lubrication and Cleaning: Add grease and clean guide rails according to manufacturer schedules to maintain stable positioner operation;

·Sensor Status Monitoring: Implement condition monitoring systems to collect key parameters such as temperature, current, and vibration for early failure warnings.

References

·Fraunhofer Institute for Production Systems and Design Technology. (2025). Multi-Axis Coordinated Control for High-Precision Welding. IPK Berlin Technical Report.

·National Institute of Standards and Technology. (2025). Dynamic Load Compensation in Welding Positioners. NIST Special Publication 1500-305.

·Dassault Systèmes. (2025). Digital Twin Framework for Welding Process Optimization. Vélizy-Villacoublay, France.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province