News Detail

ESD Protection for Welding Tables: A Critical Step in Precision Welding Operations

author:hxrtools Time:2025-07-26 18:15:18 Click:51

Safety and Precision Start with the Welding Table

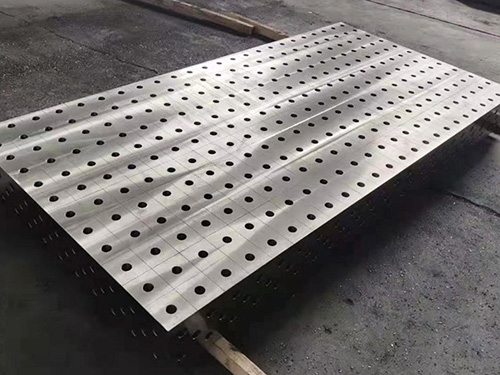

In precision industries such as electronics manufacturing, instrumentation, and high-tech repairs, the welding table is more than just a platform—it's a foundational element for safe, high-quality welding work. Yet, a commonly overlooked issue in these environments is electrostatic discharge (ESD). While often invisible, static electricity can have devastating effects on sensitive components and even pose safety hazards to workers.

In this article, we’ll explore why ESD protection is crucial for welding tables, how to implement it effectively, and how the right choices in table design and materials can directly improve operational performance.

Why Your Welding Table Needs ESD Protection

1. Protect Sensitive Electronic Components

In tasks like PCB soldering, rework, or micro-component assembly, static discharge—even as low as 30 volts—can permanently damage chips, transistors, or ICs. A standard welding table without anti-static treatment can accumulate and suddenly discharge static energy, causing irreparable harm.

2. Prevent Ignition Hazards from Static Sparks

For welding environments using flammable gases like argon or acetylene, ungrounded static buildup may ignite dangerous sparks. Proper ESD handling can prevent potential fires or explosions.

3. Ensure Consistent Welding Quality

Static interference can cause unstable arcs, spatter, or inconsistent welds—especially in TIG or MIG operations. A properly grounded welding table eliminates these irregularities, helping to maintain weld strength and precision.

3 Key Measures to ESD-Proof Your Welding Table

1. Choose the Right Anti-Static Surface Materials

Effective materials for static control include:

ESD Epoxy Resin Boards: Ideal for electronics, offering balanced surface resistance and durability.

Stainless Steel Surfaces with Grounding Straps: Great for heavy-duty welding tables; conductive but require proper grounding to avoid shock risks.

ESD Rubber Mats: Placed over the welding table surface, these provide cushioning and anti-static protection—perfect for delicate soldering tasks.

2. Implement a Grounding System (ESD Grounding)

No matter the material, grounding is essential:

Connect the welding table to ground using a 1MΩ resistor to control discharge flow;

Integrate wrist or heel straps for operators to form a human-to-equipment ESD chain;

Regularly test resistance, aiming for the 0.8–1.2MΩ range to meet ESD safety standards.

3. Control the Static-Prone Environment

The environment around your welding table also matters:

Install anti-static flooring or apply ESD epoxy coatings;

Maintain ambient humidity between 45%–65% to reduce static generation;

Require operators to wear ESD-safe garments in controlled work areas.

Balancing Strength and ESD in a Welding Table

One challenge manufacturers face is creating welding tables that are both strong enough for industrial use and safe enough for ESD-sensitive tasks. Here's how to meet both needs:

Use multi-layered table designs that combine steel structure with anti-static surface layers;

Apply modular ESD mats in high-risk areas while retaining strong welding zones;

Opt for interchangeable tops so one table supports both heavy-duty welding and sensitive soldering with minimal setup changes.

How to Build a Systematic ESD Control Plan

Installing an ESD-safe welding table is only the beginning. Effective static control requires a system-wide approach:

Classify work zones according to their ESD requirements;

Standardize grounding and resistance checks across all welding tables;

Maintain inspection logs and ESD performance audits (essential for ISO/IEC audits or electronics exports);

Train staff regularly on safe welding procedures and static control protocols.

Conclusion: A Safer Welding Table Leads to Safer, Smarter Operations

In today’s precision-driven industries, an ESD-protected welding table is not a luxury—it’s a necessity. It safeguards your components, protects your team, and ensures consistent, high-quality welds.

Whether you're soldering circuit boards, assembling high-frequency components, or conducting hybrid operations involving gas welding and electronics, a properly grounded, anti-static welding table gives you the confidence to work safely and efficiently.

Start your investment in quality from the ground up—begin with the right welding table.

References

GB/T 7714:International Electrotechnical Commission. Electrostatics–Part 5‐1: Protection of electronic devices from electrostatic phenomena‐General requirements[R]. IEC 61340-5-1, 2016.

MLA:International Electrotechnical Commission. Electrostatics–Part 5‐1: Protection of electronic devices from electrostatic phenomena‐General requirements. IEC 61340-5-1, 2016.

APA:International Electrotechnical Commission. (2016). Electrostatics–Part 5‐1: Protection of electronic devices from electrostatic phenomena‐General requirements. IEC 61340-5-1.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province