News Detail

How to Achieve Symmetrical Welding with a Welding Table: Positioning Tips and Tool Setup

author:hxrtools Time:2025-07-30 01:54:58 Click:138

Symmetrical Welding Starts with the Right Welding Table

In metal fabrication, machine frame assembly, and structural welding, symmetrical welding plays a critical role in product integrity, appearance, and long-term durability. However, factors like thermal distortion, misalignment, or poor clamping often lead to uneven or stressed welds.

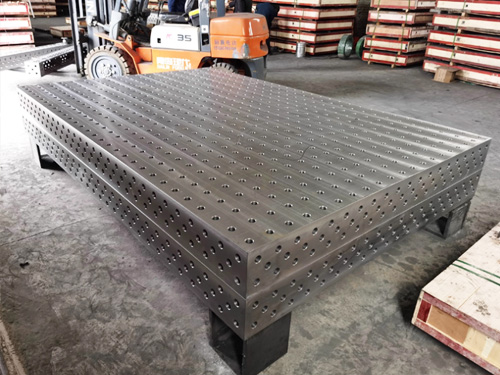

To solve this, a professional welding table becomes the foundation for success. More than just a flat surface, a high-quality welding table offers precision alignment, clamping flexibility, and repeatable positioning—key advantages for consistent symmetrical welding.

Why Is Symmetrical Welding So Important?

1. Improves Structural Stability

Weld symmetry ensures even distribution of mechanical stress, crucial in load-bearing applications like brackets, frames, or chassis components.

2. Reduces Heat Distortion

Welding generates localized heat. If applied unevenly, the resulting contraction can bend or twist parts. A symmetrical welding approach distributes heat more evenly, reducing warping.

3. Enhances Aesthetic and Assembly Consistency

For visible welds or parts that must be assembled later, symmetry adds a professional, uniform finish—and avoids costly rework.

How to Use a Welding Table for Accurate Symmetrical Welding

A precision welding table typically includes a range of features that make it the perfect platform for symmetrical layout:

1. Grid Hole System (e.g., 50mm or 100mm spacing)

·Helps with quick alignment and tool placement;

·Ensures left-right symmetry and precise angles;

·Supports consistent positioning during batch work.

2. Multi-Axis Clamping Fixtures

·Use vertical clamps, lateral push clamps, and locating pins to hold parts firmly in place;

·Prevents movement during heat cycles;

·Great for square tubing, pipe joints, or sheet structures.

3. Leveling and Adjustable Legs

·Ensures the table is flat and stable;

·Compensates for uneven workshop floors;

·Reduces angular distortion during welds.

Practical Tips for Symmetrical Welding Setup

1. Weld from the Center Outward

Begin welding from the center and alternate to each side in a mirror pattern. This balances internal stress and avoids progressive distortion.

2. Use Temporary Tacks and Pre-Clamping

Before full welding, pre-position parts with tacks and align them using the welding table's grid layout or angle guides. This ensures squareness and mirrored dimensions.

3. Add Support Tools Like Magnetic Squares or Angle Fixtures

Use magnetic blocks, L-squares, and angle guides to hold parts upright and steady. This is especially helpful for T-joints, corner frames, or rectangular box sections.

Common Use Cases for Symmetrical Welding with a Welding Table

| Application | Materials | Recommended Setup |

|---|---|---|

| Bicycle/Motorcycle Frames | Round tubing, stainless | Roller clamps + lateral alignment stops |

| Door & Window Frames | Square tubing, aluminum | L-clamps + vacuum hold-down (optional) |

| Storage Racks, Equipment | Mild steel Q235 | Side push clamps + dual-axis positioning pins |

| Perforated Plate Assembly | Thin sheets + ribs | Magnetic fixture + weighted supports for flatness |

These setups benefit greatly from a welding table that’s modular, stable, and compatible with fixture accessories.

How to Avoid Common Errors in Symmetrical Welding

·Don’t rely on visual alignment alone. Always use measurement tools and table grid systems;

·Measure distances on both sides before tacking;

·For larger workpieces, use two-person setups for better balance;

·Keep ambient conditions consistent, as temperature or airflow changes can impact weld results.

How a Welding Table Improves Repeatability and Efficiency

A properly configured welding table doesn’t just improve your first weld—it enables repeatable setups, making it easier to replicate symmetrical structures across multiple units. This is especially valuable in batch production or modular frame assembly.

·Reduce time spent measuring and clamping;

·Eliminate errors from misalignment;

·Increase output quality with fewer touch-ups or reworks.

Conclusion: Precision Begins at the Table

Whether you're welding support frames, tool carts, custom steel structures, or complex enclosures, achieving symmetrical welds is essential—and it all begins with a professional-grade welding table.

From layout accuracy to thermal distortion control, the welding table is more than just a bench—it’s the control center of welding precision. By combining the right table with smart clamping, modular tools, and correct sequencing, you’ll not only reduce fabrication errors, but also increase confidence in every weld.

Invest in symmetry. Invest in precision. Invest in a better welding table.

References

GB/T 7714:Masubuchi K. Analysis of welded structures: residual stresses, distortion, and their consequences[M]. Elsevier, 2013.

MLA:Masubuchi, Koichi. Analysis of welded structures: residual stresses, distortion, and their consequences. Vol. 33. Elsevier, 2013.

APA:Masubuchi, K. (2013). Analysis of welded structures: residual stresses, distortion, and their consequences (Vol. 33). Elsevier.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province