News Detail

What to Do When Your Welding Table Surface Warps? Effective Correction and Repair Methods

author:hxrtools Time:2025-08-02 18:14:20 Click:75

Welding Quality Starts with a Flat Surface

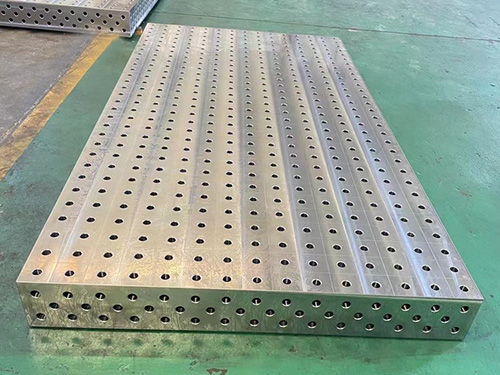

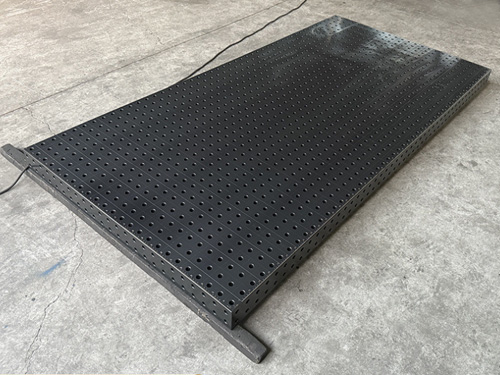

In any precision welding environment—be it metal fabrication, structural assembly, or automotive production—a welding table plays a central role. However, over time and with intense usage, welding tables may develop surface deformations, such as warping, dents, or localized high spots. These issues can directly affect weld accuracy, joint integrity, and even workplace safety.

This article outlines the common causes of welding table deformation, effective correction methods, and preventive practices to help extend the lifespan of your welding platform and optimize daily operations.

1. Why Do Welding Table Surfaces Warp?

1.1. Heat Buildup

Frequent welding in the same area leads to localized heat zones. Over time, this uneven thermal stress can cause expansion and contraction that results in surface warping or bulging.

1.2. Mechanical Impact

Placing heavy workpieces or using hammers for metal forming directly on the table can cause micro-deformation or dents, especially if the pressure is concentrated in a small area.

1.3. Uneven Support or Floor Leveling

If the table isn’t properly leveled or supported, it will experience stress imbalance over time, leading to an "X-shaped" warp or corner lift.

2. How to Fix a Warped Welding Table Surface

If the surface becomes visibly uneven or causes issues during clamping or welding, consider the following repair strategies:

2.1. Precision Scraping (For Minor Deformations ≤ 0.2mm)

·Using a scraper to shave down the high spots manually.

·Ideal for inspection-grade or calibration tables.

·Requires precision tools and experience, but effective for small deviations.

2.2. Flame Straightening (For Thermal Distortion)

·Applying targeted heat with a torch to the high spots, followed by controlled cooling.

·Induces reverse contraction to flatten the warped area.

·Best handled by experienced welders to avoid overcorrection.

2.3. Press Correction + Surface Grinding

·Heavy-duty method using hydraulic or rolling presses to flatten the surface.

·Followed by surface grinding to restore flatness across the entire platform.

·Suitable for severe deformation or large-format welding tables.

2.4. Replace Modular Sections

·If you’re using a modular welding table (with grid plates or removable panels), simply replacing the damaged segment is cost-effective.

·Temporary leveling can be achieved with high-temperature silicone pads or conductive rubber mats.

3. How to Check for Surface Flatness Issues

You can detect warping or deformation using these quick methods:

·Straightedge + Feeler Gauge: Check gaps across different directions. Flatness tolerance should ideally be ≤ 0.3 mm.

·Bubble Level or Laser Level: Detect table sag or lifted corners.

·Clamping Test: If clamps don’t hold evenly or parts tilt during welding, there’s likely a surface irregularity.

4. How to Prevent Welding Table Warping

4.1. Keep Table Level

Regularly adjust leveling feet and check for even support, especially if your workshop floor is uneven.

4.2. Distribute Heat During Welding

Avoid continuously welding in the same zone. Rotate your work area if possible to prevent heat buildup.

4.3. Use Heat-Resistant Mats

Place ceramic fiber sheets or high-temp silicone pads under high-heat zones to reduce direct thermal stress on the steel surface.

4.4. Center Heavy Workpieces

Ensure the weight is evenly distributed across the table to avoid corner sag or bending.

4.5. Clean Surface Regularly

After each session, remove slag, metal chips, and rust to avoid surface pitting or uneven weld buildup.

5. Recommended Design Features for Long-Term Stability

| Design Feature | Benefit |

|---|---|

| Modular grid-top | Easy to repair/replace warped segments |

| Heat-treated steel surface | Better resistance to heat and stress |

| Adjustable leveling feet | Maintain stability on uneven flooring |

| Coated or chromed finish | Rust resistance and high-temp durability |

Conclusion: Flat Tables, Precise Welds

A flat, reliable welding table is the foundation of any high-quality weld. Whether you’re handling structural steel, custom fabrication, or precision components, an uneven work surface can lead to poor alignment, weld defects, and rework delays.

By choosing the right repair method and implementing sound maintenance habits, you can extend your table’s lifespan and guarantee accuracy in every project.

Don’t let a warped table ruin your workflow—inspect, correct, and maintain your welding foundation today.

References

GB/T 7714:Masubuchi K. Analysis of welded structures: residual stresses, distortion, and their consequences[M]. Elsevier, 2013.

MLA:Masubuchi, Koichi. Analysis of welded structures: residual stresses, distortion, and their consequences. Vol. 33. Elsevier, 2013.

APA:Masubuchi, K. (2013). Analysis of welded structures: residual stresses, distortion, and their consequences (Vol. 33). Elsevier.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province