News Detail

Welding Table Maintenance in Humid Environments: Special Anti-Corrosion Techniques

author:hxrtools Time:2025-08-09 09:46:55 Click:59

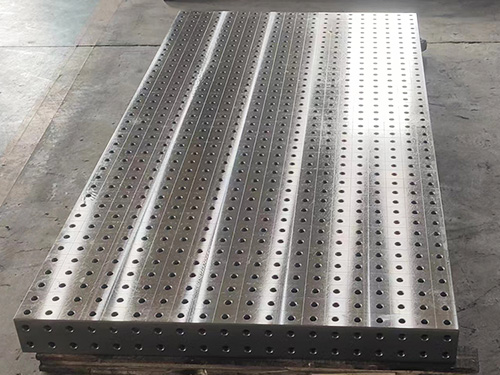

In metal fabrication and welding, the welding table is the heart of your workspace. Its flatness, durability, and strength directly influence welding accuracy and overall efficiency. However, in coastal areas, rainy seasons, or workshops with high humidity, the welding table is at risk of rust and corrosion. Even minor rust spots can affect surface precision, fixture placement, and long‑term reliability.

This article covers the impact of humidity, daily maintenance practices, and special anti‑corrosion treatment techniques to help extend the life of your welding table.

1. How Humidity Affects a Welding Table

Humid environments accelerate the oxidation process, where moisture and oxygen react with metal surfaces to form rust. For a steel welding table, this can result in:

1.Surface Rust

Rust spots degrade the appearance and compromise flatness, affecting workpiece positioning.

2.Moisture in Fixture Holes

Accumulated water in fixture holes speeds up internal corrosion.

3.Reduced Precision

Corrosion causes surface irregularities, making it difficult to maintain tight weld tolerances.

4.Shortened Service Life

Without proper care, you may need to replace the table sooner than expected, increasing costs.

2. Daily Anti‑Rust and Maintenance Practices

Even in challenging conditions, consistent maintenance can significantly slow the corrosion process.

a. Regular Surface Cleaning

After each welding session, remove slag, metal dust, and oil residues.

Use a dry cloth or brush — avoid wiping the surface with a wet cloth.

b. Apply Rust Prevention Oils or Protective Coatings

Light machine oil, rust inhibitors, or dedicated metal protection sprays can create a barrier between the table surface and moisture.

For fixture holes, use a small brush to coat the inside with rust prevention oil.

c. Maintain a Dry Workshop Environment

Install industrial dehumidifiers or place desiccants in your workshop.

Avoid placing the welding table near water sources or poorly ventilated corners.

3. Special Anti‑Corrosion Treatment Techniques

In high‑humidity regions, advanced methods can provide extra protection.

a. Surface Protective Coatings

Apply epoxy resin coatings or anti‑rust paint to isolate the surface from moisture.

Be sure to remove existing rust and polish the surface before coating to ensure adhesion.

b. Stainless Steel Overlay Plates

Install a stainless steel cover plate over the table surface to reduce direct exposure to humid air.

Stainless steel offers excellent corrosion resistance and can be replaced if damaged.

c. Cathodic Protection

Use sacrificial anodes (magnesium or zinc blocks) that corrode in place of the table surface.

This is especially effective for outdoor or coastal workshops.

d. Seasonal Deep Maintenance

Before the rainy season, perform a complete cleaning, rust removal, and re‑application of protective coatings.

Inspect fixture holes and clamps for early signs of corrosion and treat immediately.

4. Best Practices When Working in Humid Conditions

1.Avoid Covering with Damp Cloths

Covering a welding table with a damp cloth traps moisture, accelerating rust formation.

2.Prevent Liquid Spills

Keep coolant, beverages, and other liquids away from the surface during work.

3.Use Insulation Mats or Workboards

In certain welding operations, placing an insulating mat over the surface provides added moisture and electrical protection.

Conclusion

In humid environments, maintaining a welding table requires more than just occasional cleaning. A well‑maintained welding table ensures precision welding results, prolongs equipment lifespan, and reduces replacement costs. By combining daily cleaning, protective coatings, stainless steel overlays, and advanced corrosion prevention techniques, you can safeguard your table against the challenges of moisture and rust.

Whether you are a professional welder or a DIY fabricator, developing strong maintenance habits will keep your welding table performing at its best for years to come — even in the most demanding environments.

References

GB/T 7714:Lin C, Chen S. Atmospheric corrosion behavior of mild steel in the initial stage under different relative humidity[J]. International Journal of Georesources and Environment-IJGE (formerly Int'l J of Geohazards and Environment), 2018, 4(2): 33-39.

MLA:Lin, Cui, and Sanjuan Chen. "Atmospheric corrosion behavior of mild steel in the initial stage under different relative humidity." International Journal of Georesources and Environment-IJGE (formerly Int'l J of Geohazards and Environment) 4.2 (2018): 33-39.

APA:Lin, C., & Chen, S. (2018). Atmospheric corrosion behavior of mild steel in the initial stage under different relative humidity. International Journal of Georesources and Environment-IJGE (formerly Int'l J of Geohazards and Environment), 4(2), 33-39.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province