News Detail

Complete Guide to Using a 3D Welding Table in Industrial Workshops

author:hxrtools Time:2026-02-18 11:50:36 Click:126

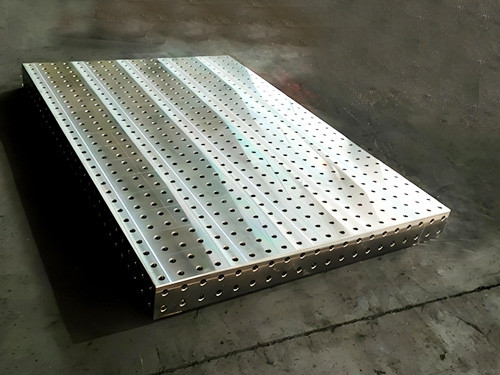

In modern fabrication environments, the 3D welding table has become a core tool for improving accuracy, speed, and repeatability. For manufacturer-level production and factory workshops, choosing and using the right 3D welding table is no longer optional, it is essential. Unlike traditional flat benches, a professional 3D welding table allows flexible positioning, rigid support, and standardized setups that transform welding operations into efficient production systems.

Whether you operate a small fabrication shop or a large-scale factory production line, understanding how to properly use a 3D welding table helps reduce setup time, minimize errors, and maintain consistent quality across batches.

What Is a 3D Welding Table?

A 3D welding table is a precision-machined work surface designed with a grid of holes on the top and sides. These holes allow clamps, stops, and fixtures to be mounted in multiple directions, creating a three-dimensional positioning system for welding and assembly tasks.

Compared with a standard industrial welding workbench, a 3D welding table offers:

·Multi-face clamping capability

·High surface flatness

·Modular fixturing options

·Improved load capacity

·Better repeatability for production work

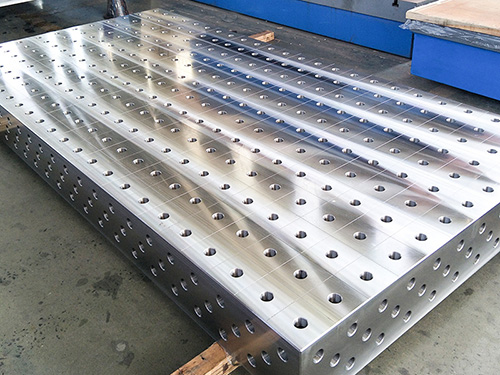

Most industrial systems combine the table with a rigid frame and, in many cases, a cast iron platform to provide long-term dimensional stability in demanding workshop environments.

Why Industrial Workshops Use 3D Welding Tables

In industrial workshops, productivity depends on consistency. A 3D welding table creates a standardized workspace where every part is positioned the same way during each production cycle.

Key advantages include:

·Faster setup: Fixtures can be reused across projects.

·Higher accuracy: Components remain square and aligned.

·Reduced distortion: Rigid surfaces limit movement during welding.

·Scalable production: Ideal for batch manufacturing in factory settings.

For manufacturers, this means fewer corrections, lower rework rates, and smoother integration into automated or semi-automated production processes.

Setting Up a 3D Welding Table for Production

Proper setup is critical for maximizing the value of a 3D welding table in industrial workshops.

1. Leveling the Table

Before any production begins, ensure the table is perfectly level. Many factory users mount the table on adjustable feet or frames to compensate for uneven floors. A level table improves alignment accuracy and prevents welding distortion.

2. Choosing the Right Fixtures

Clamps, squares, stops, and spacers are essential accessories. In manufacturer production environments, standardized fixture sets allow operators to reproduce setups quickly between batches.

3. Using the Cast Iron Platform Advantage

A cast iron platform improves vibration damping and thermal stability. During heavy welding, heat and stress can shift weaker materials, but cast iron maintains surface integrity, supporting accurate production work.

How to Use a 3D Welding Table Efficiently

Using a 3D welding table is about more than placing parts on the surface. It involves planning, positioning, and repeatability.

Positioning Components

Use the hole grid to align parts using squares and stops. This keeps assemblies perpendicular and consistent. In factory production, reference points are reused to maintain dimensional accuracy across large quantities.

Clamping Strategy

Always clamp from multiple directions. The 3D design allows side and vertical clamping, which holds parts firmly and prevents movement during welding.

Heat Control

Because welding introduces thermal expansion, distributing weld sequences evenly across the part reduces stress. The stable structure of a 3D welding table helps maintain geometry throughout the process.

Integrating 3D Welding Tables into Factory Workflows

Modern manufacturers do not treat the 3D welding table as a standalone tool. Instead, it becomes part of a broader production system.

In factory environments, these tables are often used with:

·Automated welding equipment

·Robotic arms

·Measuring tools

·Modular industrial welding workbench frames

This integration allows scalable production and supports lean manufacturing practices. When every workstation follows the same table logic, operators can move between projects with minimal retraining, increasing factory-level efficiency.

Maintenance for Long-Term Production Use

For continuous production, maintaining a 3D welding table is just as important as proper operation.

Best practices include:

·Cleaning welding spatter regularly

·Protecting the surface from corrosion

·Checking flatness periodically

·Inspecting clamps and fixtures

·Re-lubricating contact areas

Manufacturer production facilities often schedule maintenance checks to ensure the table continues supporting accurate, repeatable work throughout long production cycles.

Choosing the Right 3D Welding Table for Industrial Workshops

Not all tables are suitable for industrial production. When selecting a 3D welding table, consider:

·Material quality: A cast iron platform provides superior stability.

·Hole accuracy: Precision-machined grids ensure alignment.

·Load capacity: Must support heavy structural parts.

·Modular compatibility: Supports different production needs.

·Factory integration: Works with automated systems.

A well-chosen table becomes a long-term asset for manufacturers, supporting both flexibility and high-volume production.

Long-Term Benefits for Manufacturers

By using a professional 3D welding table, industrial workshops gain:

·Improved dimensional control

·Faster setup and changeover

·Higher repeatability

·Reduced rework

·Better production scalability

These advantages directly support factory production goals and improve overall manufacturing performance.

Final Thoughts on the 3D Welding Table in Industrial Workshops

At the center of modern fabrication is the 3D welding table. For manufacturers and factory production environments, it provides the structure, accuracy, and flexibility needed to compete in demanding markets.

By integrating a rigid frame, modular fixturing, and a stable cast iron platform, a professional 3D welding table transforms ordinary welding into a repeatable, scalable production process. Whether used for small batch assembly or full factory manufacturing, investing in the right 3D welding table ensures every weld begins with precision and ends with consistent quality.

References

GB/T 7714:Peng R, Navarro-Alarcon D, Wu V, et al. A point cloud-based method for automatic groove detection and trajectory generation of robotic arc welding tasks[C]//2020 17th International Conference on Ubiquitous Robots (UR). IEEE, 2020: 380-386.

MLA:Peng, Rui, et al. "A point cloud-based method for automatic groove detection and trajectory generation of robotic arc welding tasks." 2020 17th International Conference on Ubiquitous Robots (UR). IEEE, 2020.

APA:Peng, R., Navarro-Alarcon, D., Wu, V., & Yang, W. (2020, June). A point cloud-based method for automatic groove detection and trajectory generation of robotic arc welding tasks. In 2020 17th International Conference on Ubiquitous Robots (UR) (pp. 380-386). IEEE.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province