News Detail

How Welding Table Material Influences Welding Quality

author:hxrtools Time:2025-10-09 11:40:33 Click:174

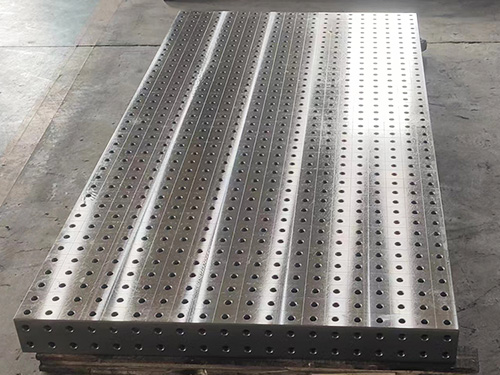

A welding table is the unsung hero of every workshop. Whether you’re joining steel structures, fabricating machinery frames, or building prototypes, the stability and quality of your welding table determine the consistency of your welds.

While most welders focus on torches, electrodes, or protective gas, they often overlook one vital factor — the material of the welding table. It directly affects heat distribution, grounding, surface accuracy, and ultimately, the strength and appearance of the finished weld.

1. The Importance of Welding Table Material

The welding table material isn’t just about hardness or weight; it defines how efficiently heat and electricity are handled during welding. A good table resists warping under temperature fluctuations and provides a stable grounding surface to maintain arc consistency.

When selecting a welding table, consider these essential properties:

·Thermal Resistance: to endure sparks and intense heat without bending.

·Surface Stability: to keep your workpiece flat and aligned.

·Electrical Conductivity: to ensure a stable current path.

·Corrosion Resistance: to prevent rust that can contaminate welds.

Choosing the wrong material can cause distortion, inconsistent weld seams, or contamination that weakens the weld joint.

2. Different Welding Table Materials and Their Characteristics

(1) Carbon Steel

Carbon steel is the most common material for welding tables. It offers great strength and heat resistance, making it suitable for heavy-duty applications. However, it’s prone to oxidation, so it needs protective coating or periodic maintenance.

Pros: Affordable, strong, magnetic (ideal for clamps).

Cons: Susceptible to rust without protection.

(2) Cast Iron

Cast iron tables are valued for their rigidity and vibration-absorbing properties. They remain flat over long periods, even under high heat and load — perfect for precision fabrication work.

Pros: Excellent stability and dimensional accuracy.

Cons: Very heavy and may crack under impact.

(3) Stainless Steel

Stainless steel welding tables are popular where hygiene and corrosion resistance are priorities — such as in food equipment or aerospace manufacturing.

Pros: Rust-proof, durable, easy to clean.

Cons: Expensive and less magnetic, limiting clamp use.

(4) Aluminum

Although lightweight and easy to move, aluminum tables are less suitable for high-temperature welding because of their low melting point and high thermal conductivity.

Pros: Portable and convenient for temporary setups.

Cons: Deforms easily under heavy heat or pressure.

3. How Material Choice Affects Welding Results

The performance of a welding table directly impacts weld quality in several ways:

·Heat Control: Tables made of cast iron or carbon steel retain heat longer, stabilizing the weld pool. Aluminum cools too quickly, increasing the risk of incomplete fusion.

·Grounding Efficiency: Conductive materials like steel ensure steady electrical flow, which helps maintain a consistent arc.

·Surface Reaction: Corrosion-resistant materials like stainless steel prevent oxidation, reducing the risk of impurities in the weld joint.

·Flatness and Rigidity: The more rigid the table, the more accurate the work — essential for structural and precision welding.

Every welder who values accuracy and consistency should consider the welding table material as a key element of the process.

4. Maintaining Your Welding Table

Even the best table requires proper maintenance to perform reliably over time. Neglecting basic care can lead to uneven surfaces and poor grounding.

Maintenance Tips:

·Clean the surface after every job to remove slag and metal residue.

·Use anti-spatter spray or light oil coating to prevent rust.

·Check for warping or dents regularly.

·Store in a dry place and cover when not in use.

These small steps protect your table and ensure that every weld remains consistent and accurate.

5. Choosing the Right Table for Your Workload

Your ideal welding table depends on your welding style and production volume:

·For precision assembly and jig work, a cast iron table is the best choice.

·For general workshop use, carbon steel tables provide excellent balance between cost and durability.

·For clean or corrosion-sensitive environments, stainless steel is ideal.

·For portable setups or field jobs, aluminum offers mobility, though not for high-heat welding.

If you’re sourcing for an industrial workshop or looking for custom solutions, working with a professional welding table supplier in China or welding table manufacturer in China is a practical option. Many Chinese factories provide bulk supply, OEM customization, and precision-machined surfaces, ensuring the stability and quality needed for professional fabrication.

6. Final Thoughts

A Welding Table is more than a piece of furniture — it’s the foundation of welding accuracy. The right welding table material controls heat distribution, ensures proper grounding, and supports long-term precision.

Whether you’re a fabrication shop, industrial manufacturer, or small welding workshop, investing in a high-quality table directly improves your welding results. Partnering with a dependable welding table manufacturer in China allows you to access durable, customizable, and bulk-supply solutions designed for modern production needs.

A strong weld starts with a solid foundation — and that foundation is your welding table.

References

GB/T 7714:Suryanto A E, Lumbantobing M A, Murwantini S, et al. Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision[J]. G-Tech: Jurnal Teknologi Terapan, 2025, 9(1): 29-39.

MLA:Suryanto, Ahmad Eko, et al. "Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision." G-Tech: Jurnal Teknologi Terapan 9.1 (2025): 29-39.

APA:Suryanto, A. E., Lumbantobing, M. A., Murwantini, S., Samudra, A., & Supriyadi, S. (2025). Design of a Welding Table with Electromagnetic Magnet Application to Enhance Welding Stability and Precision. G-Tech: Jurnal Teknologi Terapan, 9(1), 29-39.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province