News Detail

Selecting Cast Iron Platforms for Precision Milling

author:hxrtools Time:2025-10-12 12:18:10 Click:60

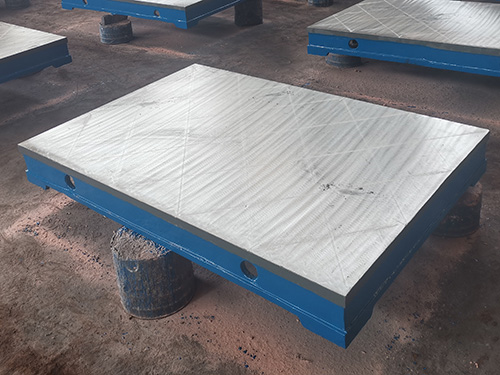

In precision machining, every fraction of a millimeter matters. While cutting tools and CNC machines often receive the spotlight, the real foundation of accuracy lies beneath — the Cast Iron Platform.

This platform serves as the base for all machining, measuring, and setup processes, ensuring every workpiece is held in perfect alignment. For workshops or factories aiming for long-term accuracy and reliability, investing in a high-quality Cast Iron Platform is as important as choosing the right milling machine.

When sourced from a reputable cast iron platform manufacturer in China, users gain access to superior craftsmanship, strong structural integrity, and bulk supply options suited for industrial-scale operations.

1. Why Cast Iron is the Ideal Material

Cast iron has long been the preferred material for milling platforms due to its unique mechanical and thermal characteristics. Its graphite microstructure gives it an edge over steel in vibration absorption and wear resistance.

Advantages of Cast Iron:

Rigidity & Strength: The dense structure of cast iron resists bending and maintains stability under heavy loads.

Excellent Vibration Damping: Minimizes chatter during milling and grinding.

Thermal Stability: Low thermal expansion keeps the surface flat even under changing temperatures.

Self-Lubricating Properties: The graphite content reduces friction and prolongs surface life.

These qualities make a Cast Iron Platform indispensable for achieving tight tolerances in milling, drilling, and inspection operations.

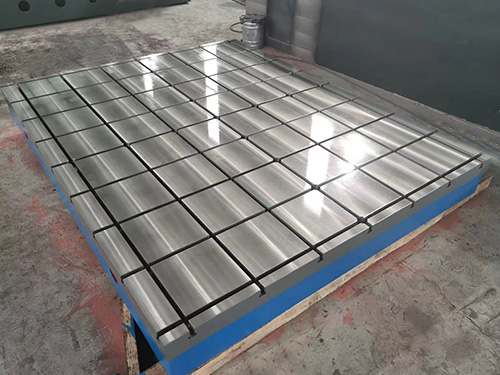

2. Surface Flatness — The Heart of Precision

A flat and stable surface is essential in any machining environment. Even minor surface irregularities can cause deviations that accumulate through the production process, affecting product accuracy.

Flatness Grades Commonly Applied:

Grade 00 / 0: Used for precision inspection or calibration in labs.

Grade 1 / 2: Ideal for production milling and general fabrication setups.

Maintaining a precise surface flatness ensures the workpiece stays perfectly aligned, providing a consistent reference plane throughout machining operations.

3. Structural Design for Long-Term Accuracy

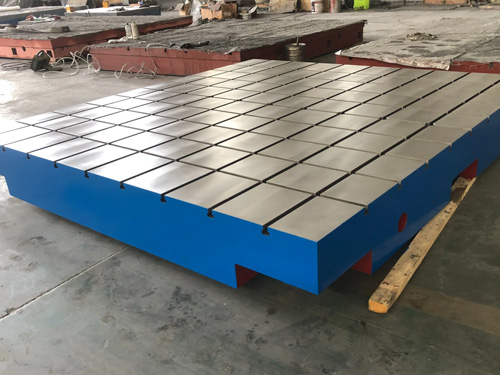

The design of a Cast Iron Platform directly affects its performance. High-quality platforms are not just flat slabs but complex cast structures engineered for stability.

Key Structural Features:

Ribbed Reinforcement: Internal ribs distribute loads evenly and reduce deformation.

Stress Relief Treatment: Aging or heat treatment eliminates internal stresses post-casting.

T-slots & Holes: Enable flexible clamping and tool positioning during milling.

When designed correctly, these features ensure the platform maintains dimensional accuracy even after years of industrial use.

4. Maintenance Practices to Preserve Precision

Even the most durable Cast Iron Platform requires regular maintenance to retain its accuracy. Neglect can lead to corrosion, surface dents, or reduced flatness.

Maintenance Tips:

Clean after each job to remove chips and coolant residue.

Apply a light protective oil to prevent rust.

Cover when not in use to keep dust and moisture away.

Re-scrape or calibrate periodically to maintain precision.

Routine maintenance extends the platform’s service life and ensures reliable performance for every milling task.

5. Choosing the Right Cast Iron Platform

Not all platforms are created equal. The right choice depends on your machining process, workpiece size, and required precision level.

Selection Criteria:

Size & Load Capacity: Choose based on the maximum component weight.

Surface Grade: Match accuracy levels to production needs.

Customization: Look for T-slot layouts or grid holes suited to your setups.

Supplier Capability: Work with a cast iron platform supplier in China that offers OEM customization and bulk supply for industry-scale orders.

Partnering with a professional cast iron platform manufacturer in China ensures not only material quality but also consistent production standards, quality checks, and cost-effective logistics.

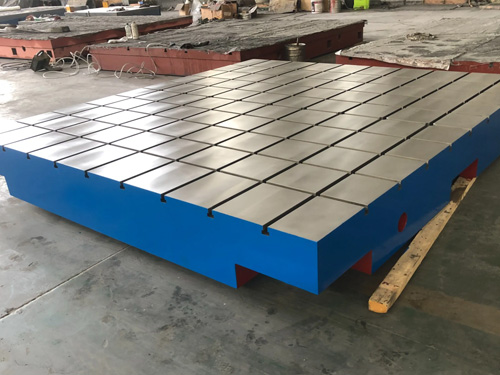

6. Applications in Modern Milling and Beyond

A Cast Iron Platform plays a critical role in multiple manufacturing environments. It’s not limited to milling but also serves in metrology, assembly, and welding fixture setups.

Typical Applications:

CNC milling and surface grinding

Fixture setup and jig alignment

Quality inspection and calibration

Tool and die assembly

Heavy mechanical base for precision instruments

Its combination of rigidity and stability ensures accuracy where even micro-level deviations matter.

7. Conclusion: Building Precision from the Ground Up

In precision manufacturing, the reliability of every process depends on a solid foundation — and that foundation is your Cast Iron Platform.

With exceptional flatness, mechanical stability, and vibration control, it ensures that every part milled or measured meets the highest accuracy standards. Whether used for small-batch fabrication or high-volume production, the Cast Iron Platform remains an irreplaceable component of precision engineering.

By sourcing directly from a reliable cast iron platform manufacturer in China, you can benefit from industrial-grade bulk supply, strict quality assurance, and long-lasting performance.

When it comes to precision milling, accuracy doesn’t start with the tool — it starts with the platform beneath it. That’s the enduring value of a Cast Iron Platform.

References

GB/T 7714:Kępczak N, Pawłowski W, Kaczmarek Ł. Cast iron and mineral cast applied for machine tool bed-dynamic behavior analysis[J]. Archives of metallurgy and materials, 2015, 60.

MLA:Kępczak, Norbert, W. Pawłowski, and Ł. Kaczmarek. "Cast iron and mineral cast applied for machine tool bed-dynamic behavior analysis." Archives of metallurgy and materials 60 (2015).

APA:Kępczak, N., Pawłowski, W., & Kaczmarek, Ł. (2015). Cast iron and mineral cast applied for machine tool bed-dynamic behavior analysis. Archives of metallurgy and materials, 60.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province