News Detail

Why a Cast Iron Platform Is Ideal for Heavy Duty Welding Tables

author:hxrtools Time:2026-02-21 12:41:38 Click:128

A cast iron platform plays a critical role in modern heavy duty welding tables where accuracy, stability, and durability are essential. Welding operations generate heat, vibration, and mechanical stress that can quickly distort weak work surfaces. For industrial workshops, fabrication lines, and structural assembly environments, choosing the right platform material directly affects weld quality and long-term productivity.

Compared with alternative materials, a cast iron platform provides exceptional flatness, vibration absorption, and load-bearing strength. Supported by professional manufacturer production and scalable factory production, cast iron platforms are widely used for bulk supply in industrial welding, fabrication, and assembly systems. This article explains why a cast iron platform is ideal for heavy duty welding tables and how production quality enhances real-world performance.

What Is a Cast Iron Platform?

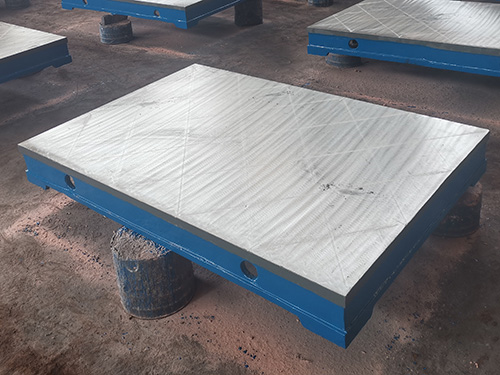

A cast iron platform is a precision-machined working surface made from high-strength cast iron materials. It is designed to support heavy components during welding, positioning, inspection, and assembly operations.

Unlike lightweight steel or aluminum tables, cast iron platforms are engineered for:

·High structural rigidity

·Excellent vibration damping

·Long-term dimensional stability

·High load capacity

These properties make a cast iron platform suitable for demanding welding environments where surface accuracy and mechanical reliability must be maintained over time.

Through controlled factory production, molten iron is cast, stress-relieved, and precision-machined to achieve consistent flatness and durability for industrial use.

Superior Stability for Heavy Duty Welding

One major advantage of a cast iron platform is its outstanding stability. Welding tables must support heavy parts, fixtures, and clamping systems without deflection. Any deformation can introduce alignment errors that affect weld quality.

Cast iron offers:

·High compressive strength

·Low elastic deformation

·Consistent geometry under load

This stability ensures that large steel structures, frames, and components remain accurately positioned throughout the welding process.

During manufacturer production, thickness control and rib structure design are optimized to enhance platform stiffness for heavy duty applications.

Excellent Vibration Damping Performance

Vibration is a major challenge in welding and fabrication. Grinding, drilling, cutting, and robotic welding all generate micro-vibrations that reduce accuracy and surface quality.

A cast iron platform naturally absorbs vibration far better than steel. Its graphite microstructure dissipates energy instead of transmitting it.

Benefits include:

·Improved welding precision

·Reduced noise levels

·Better fixture stability

·Longer tool life

This vibration damping property is one reason why cast iron platforms are widely selected for precision industrial tables.

Through precision factory production, material composition and casting processes are controlled to maximize damping performance for industrial workloads.

Heat Resistance and Thermal Stability

Welding produces high localized temperatures. A working surface must resist thermal expansion and warping caused by heat exposure.

A cast iron platform performs well because:

·It has predictable thermal behavior

·It distributes heat evenly

·It resists permanent deformation

·It maintains flatness under temperature changes

This thermal stability ensures the welding table remains accurate even after repeated heating and cooling cycles.

Advanced manufacturer production includes stress-relief treatments that minimize internal tension and improve long-term thermal performance.

Load Capacity and Structural Strength

Heavy duty welding tables often support large metal assemblies, fixtures, and tooling systems. A cast iron platform provides superior load capacity compared with lighter materials.

Key advantages include:

·High weight-bearing ability

·Resistance to bending and twisting

·Long service life under continuous load

Whether used in manual welding or automated production lines, a cast iron platform supports stable and safe operations.

Professional factory production designs rib patterns and section thickness to improve mechanical strength while controlling total platform weight.

Flatness and Precision Surface Quality

Welding accuracy depends on the flatness of the work surface. Even small deviations can affect alignment, squareness, and repeatability.

A cast iron platform is typically precision-machined after casting to achieve:

·Uniform surface flatness

·Consistent parallelism

·Reliable positioning accuracy

This makes it suitable not only for welding but also for inspection, measuring, and assembly operations.

Through strict manufacturer production controls, machining tolerances are maintained to ensure each platform meets industrial precision standards.

Durability in Industrial Environments

Industrial workshops expose equipment to impacts, spatter, dust, and chemical agents. A cast iron platform is naturally durable and resistant to surface damage.

Its advantages include:

·Resistance to wear

·Long corrosion life with proper coating

·Easy surface maintenance

·Stable performance over years of use

This durability reduces replacement frequency and maintenance cost for heavy duty welding tables.

With modern factory production, surface treatments and finishing processes further extend service life in harsh environments.

Flexible Design for Welding Table Systems

A cast iron platform can be produced in various sizes, thicknesses, and hole patterns to support different welding table configurations.

Common applications include:

·Modular welding tables

·Fixture-based assembly stations

·Robotic welding platforms

·Structural fabrication benches

Scalable manufacturer production supports customization for different load ratings, dimensions, and clamping systems for bulk industrial supply.

This flexibility makes cast iron platforms adaptable across industries such as automotive, construction equipment, machinery manufacturing, and metal fabrication.

How Production Quality Improves Performance

The real-world performance of a cast iron platform depends not only on design but also on production quality.

High-level factory production integrates:

·Controlled casting processes

·Stress relief heat treatment

·Precision machining

·Flatness inspection

·Load testing

These steps ensure every cast iron platform delivered in bulk supply offers consistent structural strength, surface accuracy, and vibration performance.

Reliable manufacturer production also improves repeatability, traceability, and long-term reliability across large-scale industrial projects.

Bulk Supply Advantages for Industrial Users

Behind every heavy duty welding table system is dependable production capacity. From raw material selection to final machining and packaging, every step influences platform reliability.

Professional manufacturer production enables customization and volume consistency. Strong factory production supports continuous bulk delivery without sacrificing mechanical accuracy or surface quality.

This production capability reduces operational risk for fabrication shops, integrators, and industrial equipment planners.

Economic Value of a Cast Iron Platform

Beyond technical performance, a cast iron platform also offers strong economic benefits:

·Reduced rework caused by misalignment

·Lower maintenance costs

·Longer service life

·Improved welding efficiency

By maintaining stable geometry and absorbing vibration, welding operations become more repeatable and productive.

With reliable factory production, cast iron platforms support both performance improvement and long-term cost control for industrial users.

Conclusion

A cast iron platform is ideal for heavy duty welding tables because it delivers superior stability, vibration damping, thermal resistance, load capacity, and surface precision. These characteristics directly improve welding accuracy, structural integrity, and long-term productivity.

Supported by professional manufacturer production and dependable factory production capability, cast iron platforms can be supplied in bulk with consistent flatness, mechanical strength, and industrial reliability.

Choosing a cast iron platform is not just a material decision, but a strategic investment in welding performance, durability, and operational efficiency across modern fabrication environments.

References

GB/T 7714:Callister Jr W D, Rethwisch D G. Materials science and engineering: an introduction[M]. John wiley & sons, 2020.

MLA:Callister Jr, William D., and David G. Rethwisch. Materials science and engineering: an introduction. John wiley & sons, 2020.

APA:Callister Jr, W. D., & Rethwisch, D. G. (2020). Materials science and engineering: an introduction. John wiley & sons.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province