News Detail

Why Cast Iron Platforms Are Critical for Large-Scale Machining

author:hxrtools Time:2026-01-18 20:15:55 Click:115

The Manufacturing Value of Cast Iron Platforms

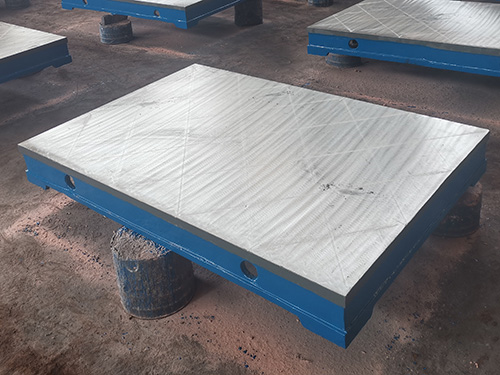

In modern industrial environments, precision is not optional—it is fundamental. For large-scale machining operations, even minor deviations can lead to significant product defects, downtime, and financial loss. This is where the Cast Iron Platform becomes indispensable. As a core structural component used in heavy machining, inspection, and assembly processes, cast iron platforms provide the stability and accuracy required by demanding industrial applications.

From the perspective of a Cast Iron Platform manufacturer, production quality and material integrity directly affect machining performance. With mature production processes and the ability to support batch supply, cast iron platforms continue to be the preferred solution for large-scale machining environments worldwide.

What Is a Cast Iron Platform?

A Cast Iron Platform is a flat, rigid base made primarily from high-grade cast iron, designed to support heavy machinery, workpieces, or precision measuring equipment. These platforms are widely used in:

·CNC machining centers

·Large lathes and milling machines

·Coordinate measuring machines (CMM)

·Heavy industrial assembly lines

Thanks to controlled casting and aging processes during production, cast iron platforms offer excellent dimensional stability over long periods of use.

Why Stability Matters in Large-Scale Machining

Load-Bearing Capability

Large-scale machining involves substantial mechanical loads. Cast iron platforms are engineered to handle high static and dynamic loads without deformation. Their high compressive strength allows them to maintain flatness even under extreme working conditions.

From a manufacturing standpoint, platforms produced through standardized casting and machining processes ensure consistency across batch production, making them suitable for large industrial facilities.

Superior Vibration Damping Performance

One of the most critical advantages of cast iron platforms is their natural vibration damping ability. During machining, vibrations can negatively affect surface finish, dimensional accuracy, and tool life.

Cast iron’s graphite microstructure absorbs and dissipates vibration energy far more effectively than steel or fabricated alternatives. This property makes cast iron platforms essential for precision machining operations that require minimal vibration interference.

Precision and Long-Term Accuracy

Dimensional Stability

Unlike fabricated steel structures, cast iron platforms undergo controlled aging during production. This process relieves internal stresses, ensuring the platform remains dimensionally stable throughout its service life.

For large-scale machining operations where recalibration is costly and time-consuming, this long-term accuracy provides significant operational advantages.

Customization for Industrial Applications

A professional Cast Iron Platform manufacturer can offer customized solutions based on application requirements, including:

·Custom sizes and thicknesses

·T-slots or threaded holes

·Surface flatness grades

·Modular designs for scalable systems

Such flexibility in production enables manufacturers to support diverse industrial needs while maintaining batch supply capability for large projects.

Durability and Cost Efficiency

Long Service Life

Cast iron platforms are known for their durability. With proper surface treatment and maintenance, they can operate reliably for decades. This long service life reduces the total cost of ownership, making them a cost-effective solution for large machining facilities.

From a production perspective, consistent material quality and controlled casting processes ensure that each platform meets industrial durability standards.

Applications Across Industries

Cast iron platforms are widely adopted across multiple sectors, including:

·Heavy equipment manufacturing

·Aerospace component machining

·Energy and power generation

·Automotive tooling and inspection

·Industrial measurement and calibration

Their adaptability and proven performance make them a foundational component in modern manufacturing infrastructure.

Manufacturing Process: Why Quality Production Matters

The performance of a cast iron platform depends heavily on its manufacturing process. Key stages include:

·Material selection and melting

·Precision casting and mold control

·Stress relief and aging treatment

·CNC machining and surface grinding

·Final inspection and flatness verification

Manufacturers with advanced production capabilities and quality control systems are better positioned to deliver platforms suitable for large-scale machining and batch supply requirements.

Conclusion: Cast Iron Platforms as an Industrial Essential

In large-scale machining environments, the Cast Iron Platform is not merely a supporting structure—it is a critical factor in achieving precision, stability, and efficiency. Its superior vibration damping, load-bearing strength, and long-term dimensional stability make it irreplaceable in demanding industrial applications.

For buyers seeking reliable solutions, working with an experienced Cast Iron Platform manufacturer with proven production capacity and batch supply capability ensures consistent quality and dependable performance. As industrial machining continues to evolve, cast iron platforms remain a cornerstone of precision manufacturing.

References

GB/T 7714:Zhang Y, Jarosinski W, Jung Y G, et al. Additive manufacturing processes and equipment[M]//Additive manufacturing. Butterworth-Heinemann, 2018: 39-51.

MLA:Zhang, Yi, et al. "Additive manufacturing processes and equipment." Additive manufacturing. Butterworth-Heinemann, 2018. 39-51.

APA:Zhang, Y., Jarosinski, W., Jung, Y. G., & Zhang, J. (2018). Additive manufacturing processes and equipment. In Additive manufacturing (pp. 39-51). Butterworth-Heinemann.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province