News Detail

Why Granite Platforms Are Essential for Precision Metrology

author:hxrtools Time:2025-10-15 13:33:19 Click:122

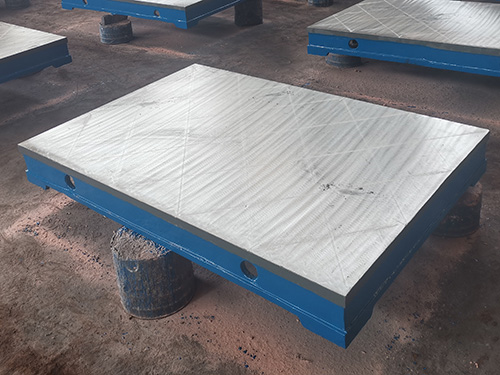

In precision measurement, the smallest variation can make or break accuracy. Every gauge, coordinate measuring machine (CMM), or inspection instrument depends on a foundation that won’t shift, bend, or distort — and that foundation is the Granite Platform.

Favored by metrology professionals around the world, granite surface plates deliver consistent performance under conditions that challenge other materials. When sourced directly from a granite platform supplier in China, they offer an ideal balance of accuracy, durability, and factory-scale supply for industrial users.

1. The Critical Role of Granite Platforms in Metrology

A Granite Platform serves as the stable, flat reference plane on which precision instruments rest and measurements are made. Its role is simple but irreplaceable: to provide an unchanging surface that ensures all dimensional readings are consistent and traceable.

Because granite maintains its form even under fluctuating temperatures or loads, it has become the preferred choice for inspection setups that demand long-term accuracy.

Key Purposes:

·Forms a zero-reference plane for dimensional inspection and calibration

·Provides a non-deforming base for measuring tools and CMMs

·Absorbs vibration during fine measurement

·Maintains surface integrity under thermal and mechanical stress

2. Why Granite Surpasses Metal Surfaces

Compared to steel or cast iron, granite’s inherent stability gives it an unbeatable advantage in metrology applications.

Thermal Neutrality

Granite’s coefficient of thermal expansion is remarkably low. That means it won’t expand or contract noticeably as ambient temperatures change — crucial for precision labs or inspection facilities.

Non-Magnetic and Chemically Stable

Granite’s non-magnetic nature prevents interference with electronic or magnetic sensors. It also resists rust, oxidation, and chemical corrosion, unlike metallic platforms.

Superior Damping Capability

Its crystalline grain structure naturally absorbs vibration and mechanical shock, minimizing external influences during sensitive measurements.

Durability and Long Service Life

Granite resists scratches and deformation, even with continuous use. With minimal upkeep, a Granite Platform can serve reliably for decades without losing its accuracy.

For these reasons, granite consistently outperforms other platform materials used in measurement and inspection.

3. Accuracy Grades and International Standards

Every granite surface plate is manufactured to meet established metrology standards such as ISO 8512, DIN 876, or GB/T 20428. These define the acceptable tolerances for flatness and surface quality.

Typical Grades Include:

·Grade 00: Laboratory-level accuracy, ideal for calibration masters.

·Grade 0: Standard for precision inspection in QC labs.

·Grade 1: Suitable for general workshop and production settings.

Before leaving the factory, each Granite Platform undergoes fine lapping and inspection using high-accuracy instruments such as autocollimators or laser interferometers.

A professional granite platform manufacturer in China can also provide custom-built bulk supply, ensuring consistency across large measurement setups.

4. Maintenance and Care for Accuracy Retention

Although granite is extremely stable, proper care keeps it performing at top precision for years.

Routine Maintenance Tips:

·Clean before and after use with a lint-free cloth to remove dust and oil.

·Keep sharp tools or heavy machinery off the surface to avoid scratches.

·Store in a temperature-controlled room, away from direct heat or sunlight.

·Calibrate periodically according to usage intensity and inspection frequency.

Following these practices helps preserve the accuracy and longevity of any Granite Platform used in metrology.

5. How to Choose the Right Granite Platform

Selecting the right platform depends on your specific measuring environment, space constraints, and accuracy requirements.

Selection Guidelines:

·Size & Thickness: Choose sufficient dimensions to support the instrument and workpiece.

·Grade & Accuracy: Match the surface flatness to your metrology application.

·Support Frame: Ensure the platform is properly supported to prevent bending.

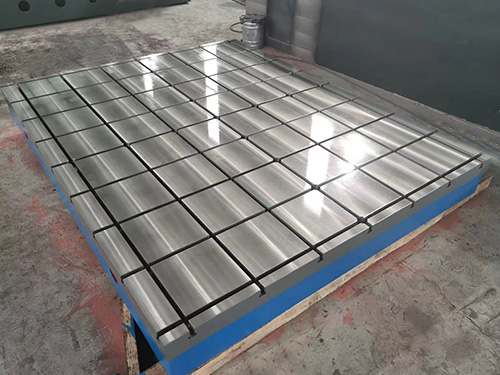

·Customization: Many granite platform suppliers in China offer OEM services — adding T-slots, threaded inserts, or mounting holes for CMMs and gauges.

When sourced directly from a Chinese manufacturer with bulk production capability, you gain both high precision and cost efficiency, with the assurance of factory calibration.

6. Industrial and Laboratory Applications

The Granite Platform has become a standard fixture in modern quality control and metrology environments, serving in:

·CMM Bases: Provides structural rigidity for accurate dimensional scanning.

·Optical or Laser Measurement Systems: Minimizes vibration-induced deviation.

·Gauge Calibration Stations: Ensures a stable reference surface for comparative checks.

·Tool and Mold Inspection: Supports high-precision geometric evaluation.

Its non-reactive, thermally stable nature ensures consistent accuracy even in long-term industrial use.

7. Conclusion: The Core of Measurement Precision

The Granite Platform stands as the silent foundation behind nearly every precision measurement. Its exceptional flatness, vibration resistance, and dimensional stability make it indispensable in metrology laboratories and production environments alike.

For professionals seeking uncompromised accuracy, working with a certified granite platform manufacturer in China provides access to bulk supply, consistent quality, and global shipping — all rooted in the tradition of precise craftsmanship.

Ultimately, the pursuit of accurate measurement begins and ends with a single element: a perfectly finished Granite Platform.

References

GB/T 7714:Skattum G A. Estimating thermal effects for granite surface plate calibration[J]. NCSLI Measure, 2015, 10(1): 50-58.

MLA:Skattum, Gordon A. "Estimating thermal effects for granite surface plate calibration." NCSLI Measure 10.1 (2015): 50-58.

APA:Skattum, G. A. (2015). Estimating thermal effects for granite surface plate calibration. NCSLI Measure, 10(1), 50-58.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province