News Detail

How to Identify a High-Quality Cast Iron Platform

author:hxrtools Time:2026-02-05 22:44:38 Click:198

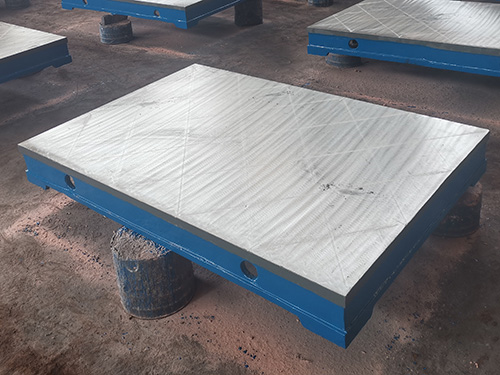

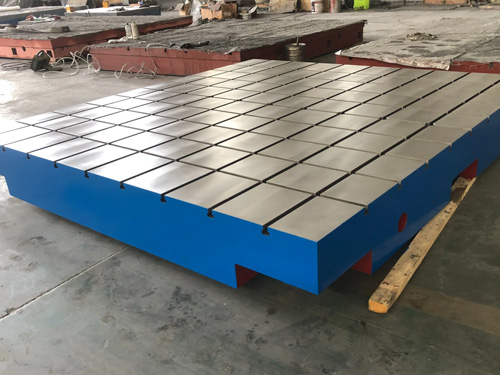

What Is a Cast Iron Platform?

A cast iron platform is a rigid, load-bearing surface commonly used in industrial, construction, and manufacturing environments. It provides a stable working base for equipment, inspection, machining, or elevated access. Compared with fabricated steel structures, cast iron platforms are valued for their mass, vibration resistance, and dimensional stability.

The main function of a cast iron platform is to support heavy loads while maintaining flatness and structural integrity over long periods of use. Whether installed in workshops, plants, or assembly areas, a well-designed platform helps improve accuracy, safety, and operational efficiency.

High-quality platforms are typically produced through standardized factory production, ensuring consistency in material properties and geometry.

Material Composition and Structural Integrity

The foundation of a reliable cast iron platform lies in its material composition. Most platforms are made from gray cast iron or ductile cast iron, both known for excellent compressive strength and damping capacity.

Gray cast iron contains graphite flakes that absorb vibration, making the platform ideal for precision operations. Ductile cast iron, on the other hand, offers higher tensile strength and impact resistance. A high-quality platform uses controlled chemical composition to balance strength and stability.

Uniform microstructure is another key factor. Poor casting practices can create internal porosity, shrinkage cavities, or inclusions that weaken the platform. Through controlled manufacturer production, each cast iron platform is inspected to ensure consistent density and internal quality.

Load Capacity and Stability Evaluation

Load capacity is one of the most important indicators when selecting a cast iron platform. A reliable platform must support static and dynamic loads without bending, cracking, or losing flatness.

Evaluation begins with thickness design and rib reinforcement beneath the surface. These structural elements distribute forces evenly across the platform. The heavier mass of cast iron naturally increases stability, reducing movement when machinery or operators are placed on the surface.

In professional environments, platforms undergo load testing during factory production to verify that they meet specified safety margins. This testing ensures that the cast iron platform maintains performance even under continuous industrial stress.

Surface Finish and Machining Accuracy

A high-quality cast iron platform must provide a precise and smooth working surface. After casting, the platform is typically machined to achieve accurate flatness and parallelism.

Surface finish directly influences performance. A poorly machined platform can introduce unevenness that affects equipment alignment or operator safety. Precision grinding and milling processes help achieve tight tolerances across the entire platform area.

Additionally, anti-slip textures or protective coatings may be applied to improve usability and corrosion resistance. Through consistent production standards, manufacturers ensure that every cast iron platform maintains uniform surface quality.

Manufacturing Process and Quality Control

The reliability of a cast iron platform depends heavily on the manufacturing process. It begins with pattern design, mold preparation, molten metal pouring, controlled cooling, and post-casting heat treatment.

Controlled cooling reduces internal stress and prevents warping. Heat treatment further stabilizes the structure, improving long-term dimensional accuracy. Without these steps, platforms may deform after installation.

Quality control procedures include dimensional inspection, hardness testing, and visual examination. A professional manufacturer factory environment allows large-scale platforms to be produced with repeatable accuracy and predictable performance for bulk supply markets.

Safety Performance and Durability

Safety is a core concern when using a cast iron platform in industrial settings. A high-quality platform must resist cracking, surface wear, and fatigue over time.

Cast iron’s inherent resistance to compression and vibration makes it ideal for long-term applications. When combined with reinforced structure and proper machining, the platform maintains stability even in high-traffic environments.

Durability also depends on environmental protection. Corrosion-resistant treatments extend the service life of the cast iron platform in humid or chemical-exposed areas. Regular inspection further ensures ongoing safety performance.

Manufacturer Production and Factory Supply Advantages

Choosing a cast iron platform from a professional manufacturer offers advantages beyond basic functionality. Factory-controlled production ensures consistent metallurgy, geometry, and surface accuracy across batches.

Through scalable factory supply, businesses can deploy identical platforms across multiple workstations, ensuring uniform workflow and safety standards. Bulk production also allows better cost efficiency without sacrificing quality.

A structured production system ensures every cast iron platform follows standardized testing and inspection before reaching the end user.

Common Applications of Cast Iron Platforms

A cast iron platform is widely used in machine shops, inspection rooms, assembly plants, and heavy equipment maintenance facilities. Its vibration damping makes it ideal for measuring equipment, alignment tasks, and machining operations.

In construction and industrial assembly, platforms provide stable elevated surfaces for tools and operators. In manufacturing, they support fixtures, gauges, and precision instruments.

Thanks to robust factory production and manufacturer support, cast iron platforms remain reliable assets in demanding industrial environments.

Conclusion: Choosing the Right Cast Iron Platform

Identifying a high-quality cast iron platform requires evaluating material composition, load capacity, surface finish, manufacturing process, and safety performance. Each of these factors directly affects stability, durability, and usability.

By sourcing from professional manufacturer production and dependable factory supply systems, users gain access to platforms with consistent quality and predictable performance.

A well-engineered cast iron platform is not just a support surface—it is a long-term investment in precision, safety, and industrial efficiency.

References

GB/T 7714:Mane S S, Wankhede P A. INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND TECHNOLOGY (IJMET)[J]. Journal Impact Factor, 2012, 3(2): 38-45.

MLA:Mane, S. S., and P. A. Wankhede. "INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND TECHNOLOGY (IJMET)." Journal Impact Factor 3.2 (2012): 38-45.

APA:Mane, S. S., & Wankhede, P. A. (2012). INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING AND TECHNOLOGY (IJMET). Journal Impact Factor, 3(2), 38-45.

HOT PRODUCTS

HOT PRODUCTS

CONTACT US

CONTACT US

—— E-mail:project@haoranmj.com

—— Whatsapp:+86 18932785670

—— Tel:+86 18932785670

—— Add:Across from Sanjing Distillery on Road 4, Botou Economic Development Zone, Cangzhou City, Hebei Province